Holtey Classic Hand Planes

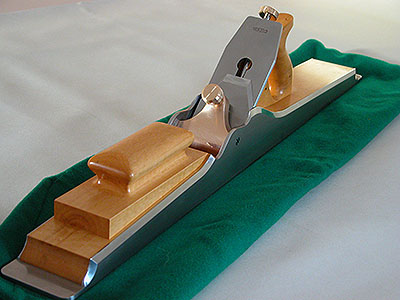

A1 Panel/Jointer plane

This infill plane is designated A1 and the same profile/pattern was used through the entire range of sizes. These planes start at 13½" to 17½" for panel planes,

and 17½" to 28½" for jointers.

In the Norris catalogue it states that all sizes are available up to 36", although very few, if any, were made at the largest sizes.

Normally I recommend jointers only up to 22½" but I have made a small number of 28½" as special commissions.

In the Norris catalogue it states that all sizes are available up to 36", although very few, if any, were made at the largest sizes.

Normally I recommend jointers only up to 22½" but I have made a small number of 28½" as special commissions.

precision engineering without compromise

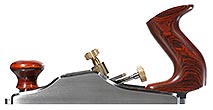

A1 Smoother

This is an A1 14 1/2” smothing plane in the Norris style, with Cocobolo infill, dovetailed steel sides and bottoms with gunmetal fittings and a 2 1/2” x 3/16” thick blade in my A2 steel.

As I now want to concentrate on my own designs I am unlikely to be making this plane again. It is a sad statement to say this but there are far too many other projects piling up. I have detailed the making of this plane before which is available in my blog.

This is a very good all round plane because it is on the larger side for smoothing but also has a good capability for jointing.

The plane is an absolute joy to use.

As I now want to concentrate on my own designs I am unlikely to be making this plane again. It is a sad statement to say this but there are far too many other projects piling up. I have detailed the making of this plane before which is available in my blog.

This is a very good all round plane because it is on the larger side for smoothing but also has a good capability for jointing.

The plane is an absolute joy to use.

Although I decided not to show any workshop images I had to show this one (left) as it is on the last leg home, though there are still many hours of lapping and flattening to go -

it is not practical to surface grind. The dovetails and rivets are being flushed off in a vertical mill.

The picture (left) shows the adjuster and blade bed. Also showing the lever cap retaining spigots and the captive recess in the lever cap. This allows for approximately two complete turns before the lever cap can be removed. This is a great improvement to the original infill planes where the lever caps were permanently captive.

It is because of these innovations I have been inspired to design my own planes.

The picture (left) shows the adjuster and blade bed. Also showing the lever cap retaining spigots and the captive recess in the lever cap. This allows for approximately two complete turns before the lever cap can be removed. This is a great improvement to the original infill planes where the lever caps were permanently captive.

It is because of these innovations I have been inspired to design my own planes.