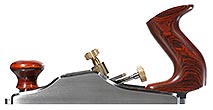

Holtey Classic Hand Planes

Karl Holtey

When people ask what I do for a living, the answer to the question has never been easy and even now speaking to the initiated it is still no easier. So I shall go back to the beginning.The first hand plane that really inspired me was an absolutely super condition Norris 17 ½” A1, over 25 years ago. From that day to this the whole idea of building hand planes the way I do has been a one man crusade.

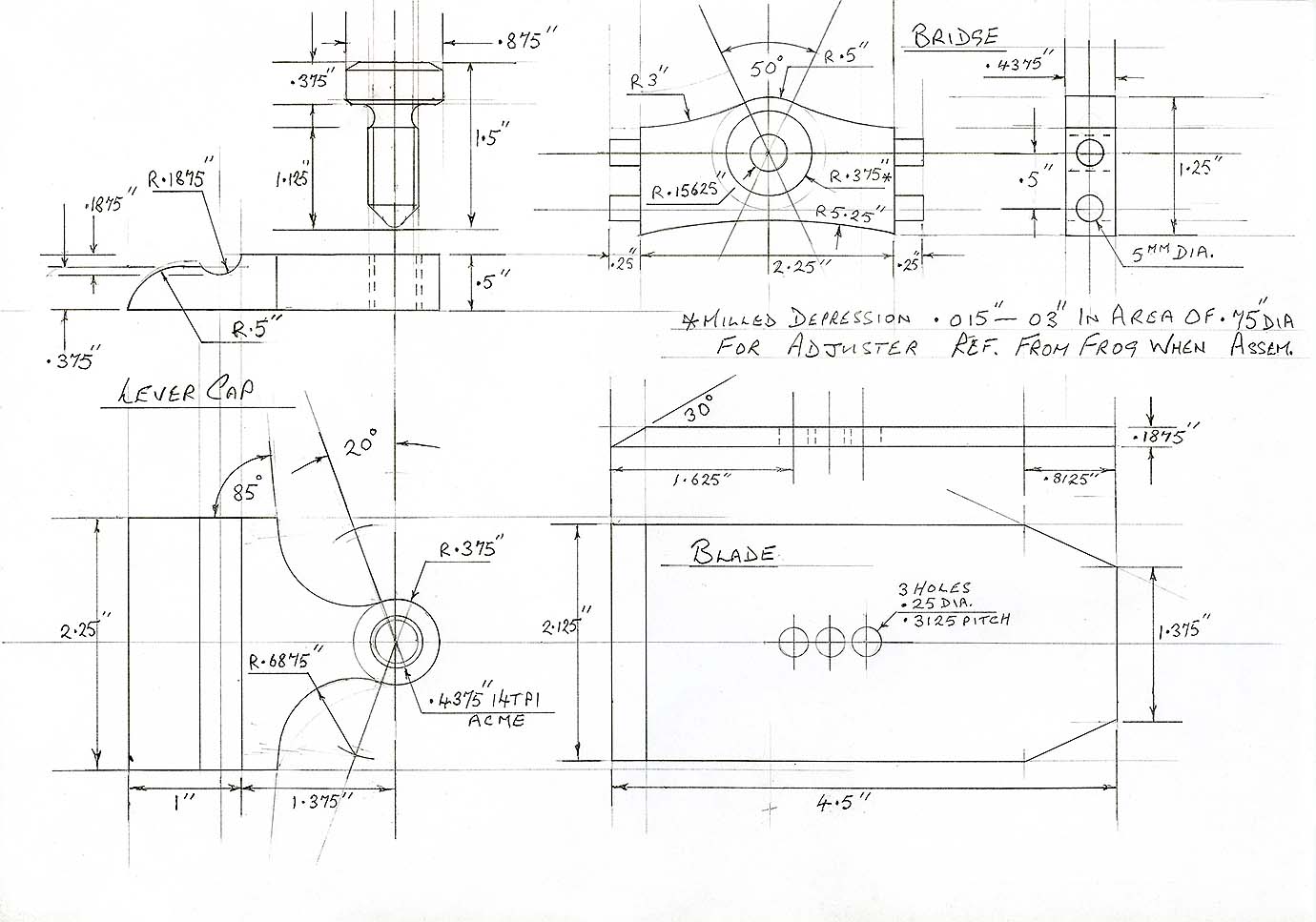

Having started out as a cabinet maker and also some years in joinery and with an interest in model engineering, I decided I had the ability to make a hand plane to at least the same standard as the Norris A1 I had read about. My understanding of what goes into making a plane has been helped by having the good fortune to be asked to restore antique hand planes.

Over the years contact with other craftsmen, dealers, collectors and metallurgists has enabled me to improve all the time. Each time I buy a new machine or

tool it doesn’t seem to make me faster but instead helps me to increase my standards. My philosophy about standards has never been a static situation, I always

try to make the next hand plane better than the one that preceded it.

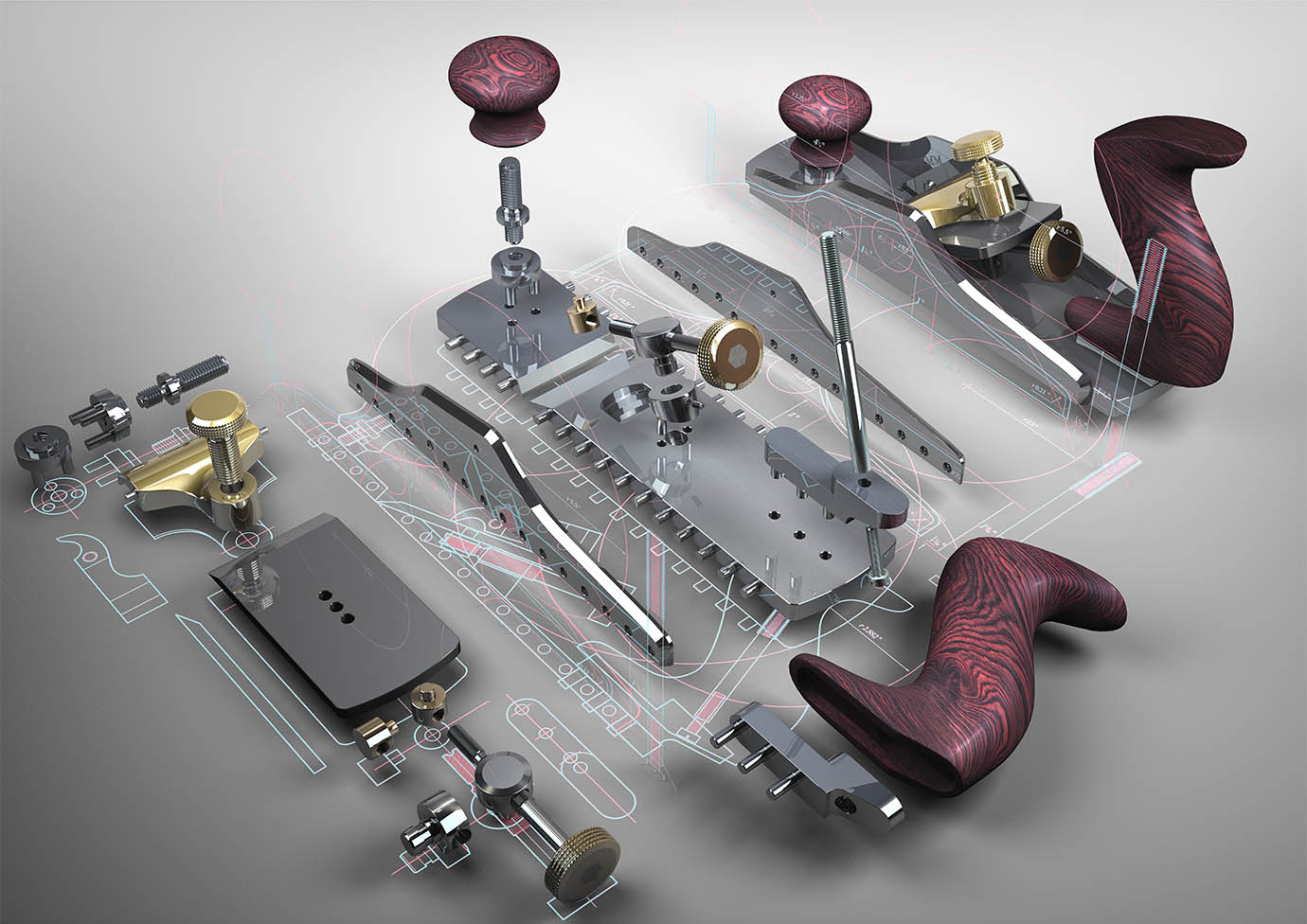

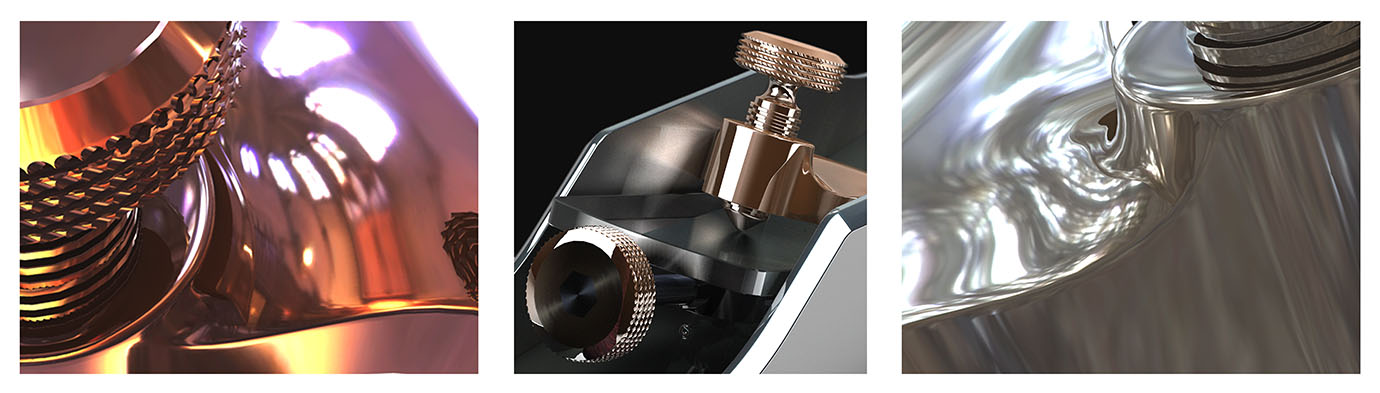

There has always been a trend to accept, when considering antiques, that their quality cannot be achieved today. It doesn’t take a great thinker to realise what a misguided concept this is, especially when you consider the advances in technology in the last 100 years. My work is regarded by many as the bench mark in precision and quality for these types of tools.

I have a small tool room which is far better equipped than most of the back garden one man enterprises making infill planes today. I would consider myself as somewhat unique, in that I am not a manufacturer and something a little bit more than a maker. Contrary to some opinion these planes are as near to handmade as you will ever get with this kind of finish and precision. I think it is unlikely anyone who follows me will achieve the same quality and precision, as there is no financial gain or reward with these objectives, I just survive.

I do use traditional materials except for the blades where I have used metal alloys such as PM metals and A2 tool steel. I was the first to use these in the making of plane blades, since then many manufacturers have followed using A2.

I need to stay ahead with further improvements after all the competition I have spawned. I have made my thoughts on the inherent problems of infill planes clear elsewhere.

My 98 series designs leave infill behind and look to the future - this is the way I hope to push design of the hand plane forward.

There has always been a trend to accept, when considering antiques, that their quality cannot be achieved today. It doesn’t take a great thinker to realise what a misguided concept this is, especially when you consider the advances in technology in the last 100 years. My work is regarded by many as the bench mark in precision and quality for these types of tools.

I have a small tool room which is far better equipped than most of the back garden one man enterprises making infill planes today. I would consider myself as somewhat unique, in that I am not a manufacturer and something a little bit more than a maker. Contrary to some opinion these planes are as near to handmade as you will ever get with this kind of finish and precision. I think it is unlikely anyone who follows me will achieve the same quality and precision, as there is no financial gain or reward with these objectives, I just survive.

I do use traditional materials except for the blades where I have used metal alloys such as PM metals and A2 tool steel. I was the first to use these in the making of plane blades, since then many manufacturers have followed using A2.

I need to stay ahead with further improvements after all the competition I have spawned. I have made my thoughts on the inherent problems of infill planes clear elsewhere.

My 98 series designs leave infill behind and look to the future - this is the way I hope to push design of the hand plane forward.