One of those very short moments – job satisfaction

January 1, 2020

November 21, 2019

November 20, 2019

Workshop blog no 25 No 985

This is the last chance to take this kind of picture before I assemble the planes. I cannot possible imagine anyone else ever going down this route. As with all my planes it has to be better than the one that proceeded it. This is the last 10 I am assembling. To quote a maxim – when they’re gone they’re gone.

November 14, 2019

Workshop Blog no 24 – No 985

Stainless steel bolts for the No 985. 250 of them. All handmade. Never want to see one again. I would be embarrassed to say how long they took. It is important that they were made to a high precision, but will be hidden when the work is finished.

There are only a small number of these planes unsold

September 21, 2019

Workshop blog no 23 – No 985

This is unusual for me because I think showing off shavings could be a little sad. Not many people tell you the wood they are using but here I have planed a very wild piece of Boxwood out of the scrap bin. As you can see there is a large knot near the edge so there is a lot of alternating grain. I was pushing off quite a thick shaving at 2 thou with no tear out at all. Then I was able to finish off at 1 thou without revisiting the oil stone. No doubt the enthusiast could improve on this performance as I don’t have the time to play. This is my new blade in stainless – that is all I am saying.

June 3, 2019

Workshop Blog 25 – No 985

Still plodding along.

The first picture is to try and give you some idea of the work that goes into these planes. The picture should be self explanatory. It shows some of the metal (stainless) work and handles. From this you can see it includes spines that are threaded and keyed ready for cementing with epoxy into the handles. This gives the kind of strength and rigidity which would surpass what is normally found on a closed handle.

It is this kind of work that makes me one of life’s misfits.

Now I am on to the handle shaping which is basic hand work. My CNC machine doesn’t seem to have a button for this job. I find pleasure in the wood taking shape and interesting contrasts come to life.

Here the chosen wood is a Honduras Rosewood – Dalbergia stevensonii – still lots of work to be done. The price of the plane goes up and up with the pain of the work.

May 8, 2019

Workshop blog no 23 – No 985

Looking back on the last posting and it has been a whole month – I have been away for a while and life just seems to get in the way of work sometimes. Was having a look at what retirement could be like, but I can’t afford it!

A quick photo of work on the upper blade bed. The amount of work here was greatly underestimated in my planning. It is always difficult to estimate in the first place and then I keep tweaking and tuning as I go along. Why spoil the ship for a ha’porth of tar. I don’t think I will ever be rich but I can aim to be the best.

I will retain radio silence for a little bit longer until I have something more interesting to show.

April 8, 2019

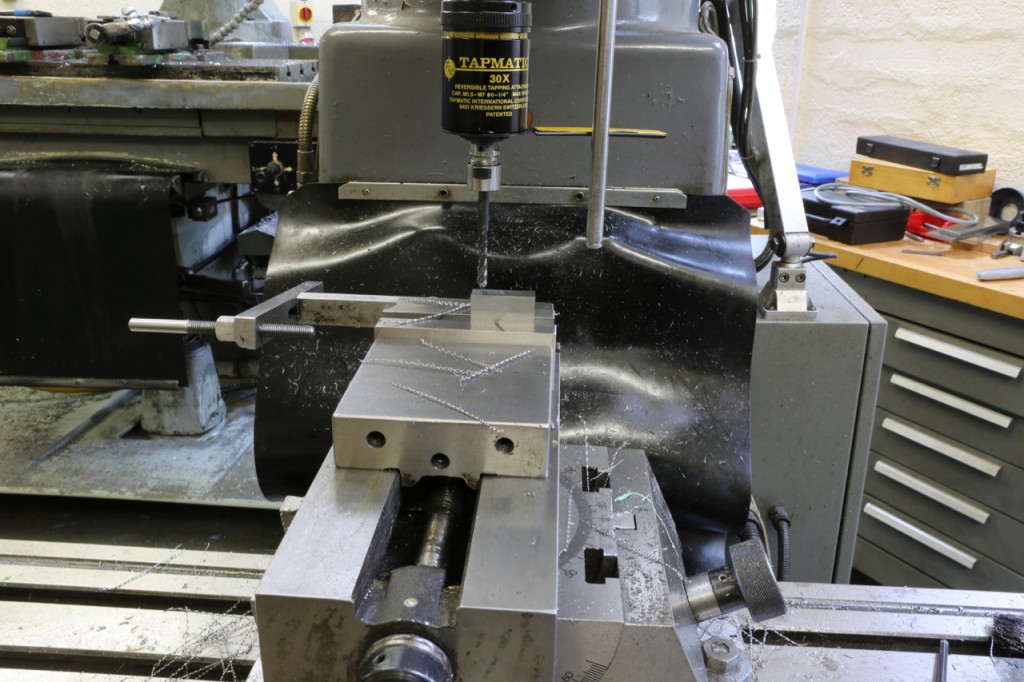

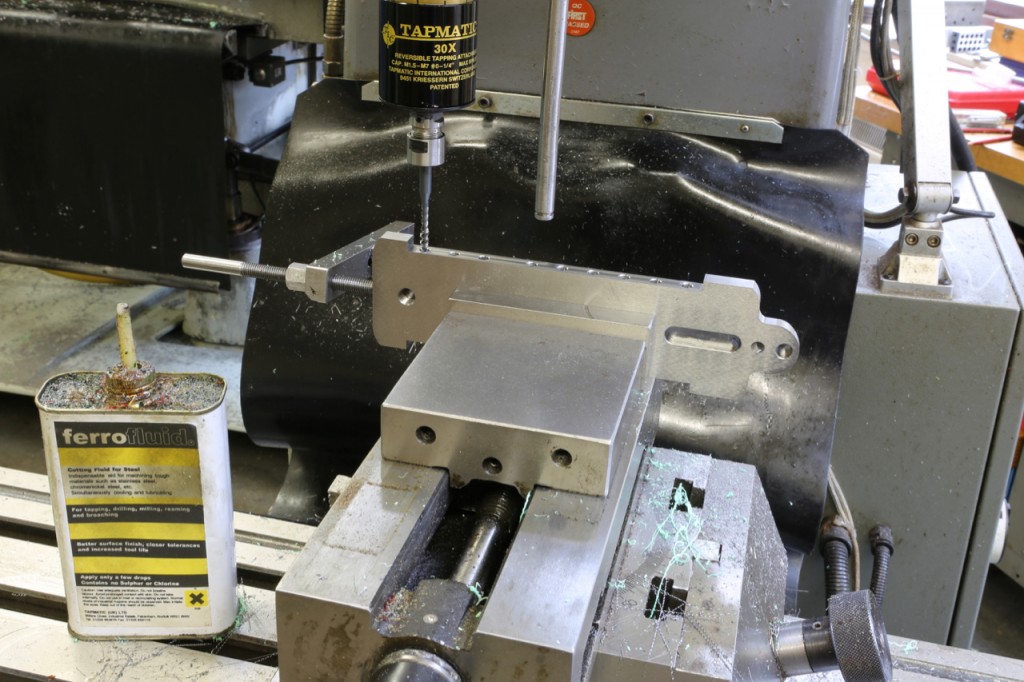

Workshop blog no 22 – No 985

I wish this stainless stuff would cut as easy as the plastic. The plastic is very useful for setting up.

This is quite a heavy cut for my machine and she it is getting quite old. So it always nice to put these jobs behind me.

With the recesses now cut I am still not out of the woods as the drilling for the custom made screws makes me worried about tool breakage – set up is critical. The drilling stage is three different tools.

The tapping is the most dangerous part of this stage and I always take a sigh of relief if I finish without incident. One tap breakage means I am minus a plane – that is a lot of work gone down the toilet! It is not like a production line and every plane is relied on to show a profit.

Every stage of this work has to be a well planned operation to avoid any casualties.

April 4, 2019

March 19, 2019

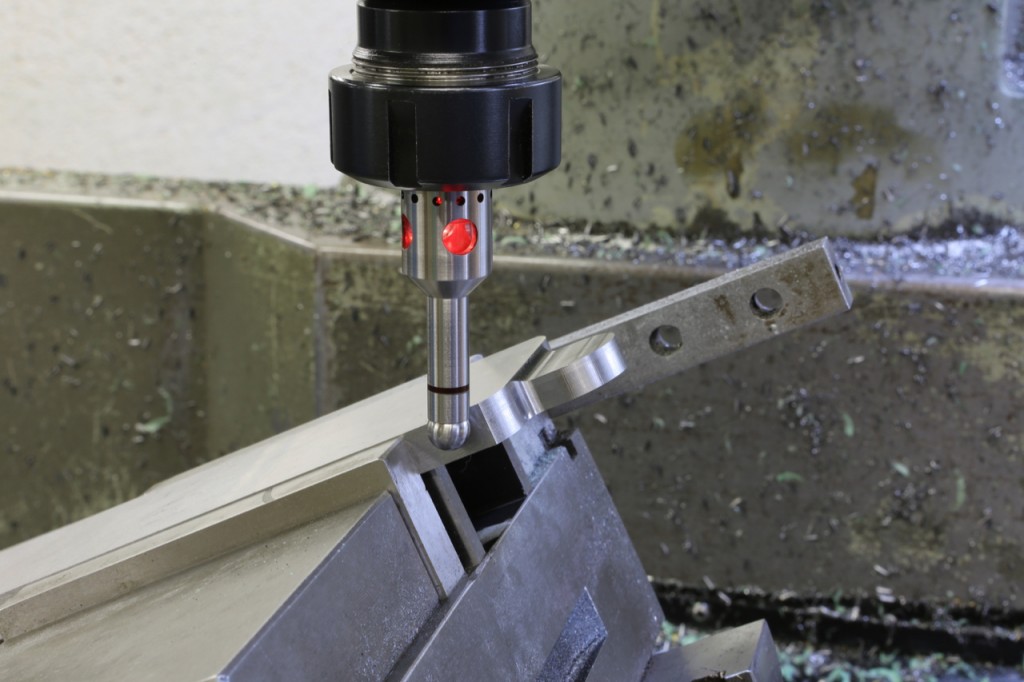

Workshop Blog no 18 – No 985

Setting up for the completion of the rear handle carrier.

The handle carrier now finished with drilling and counterbore and with streamlining facet.

No 983 Commentary

I want to go back and take the time to explain the development and design of the No 983. I will be updating the website with this during next week. When I made this plane I only did a limited number which sold out quickly so I had to make another batch. It is very satisfying to complete a design but I am not going there again as the work is far too much. I won’t make the mistake of selling the last one (mine!) again, but I do have two left for sale.