It might seem that things have been quiet here but in actual fact it is the opposite. I have been too busy to post and I have had a number of issues, including a small injury, which seem to compound. Old age seems to be catching up on me and I don’t know if I am getting slower or fussier over the work (obviously I favour the latter ![]() ).

).

It had been my intention not to do any more posts until I had a finished plane, but I just wanted to assure you all that I am alive and well. The project is nearing its end.

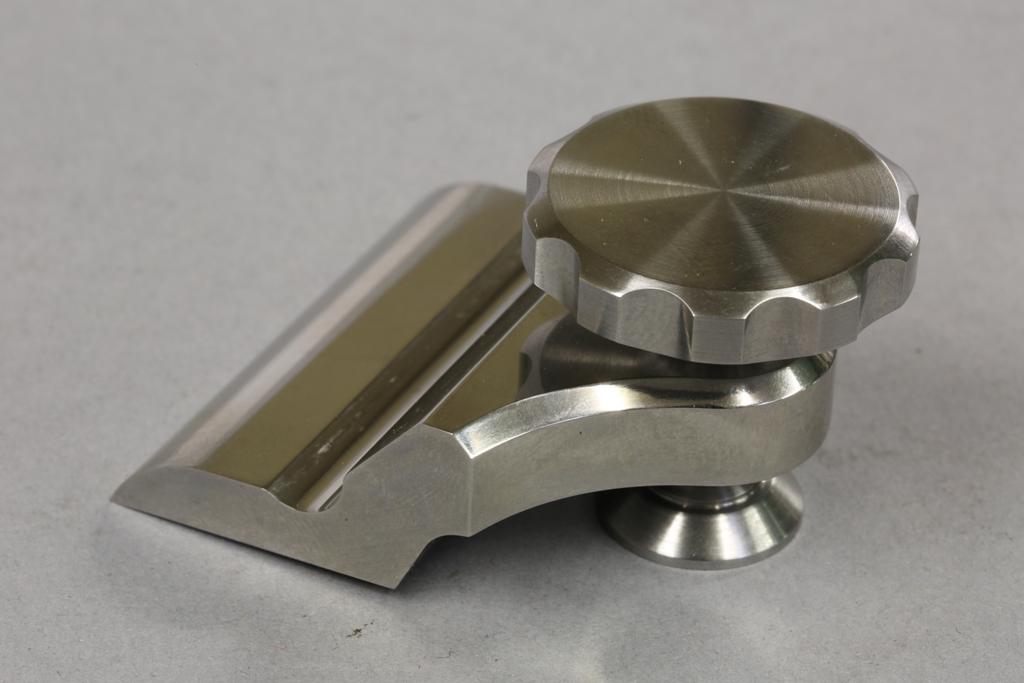

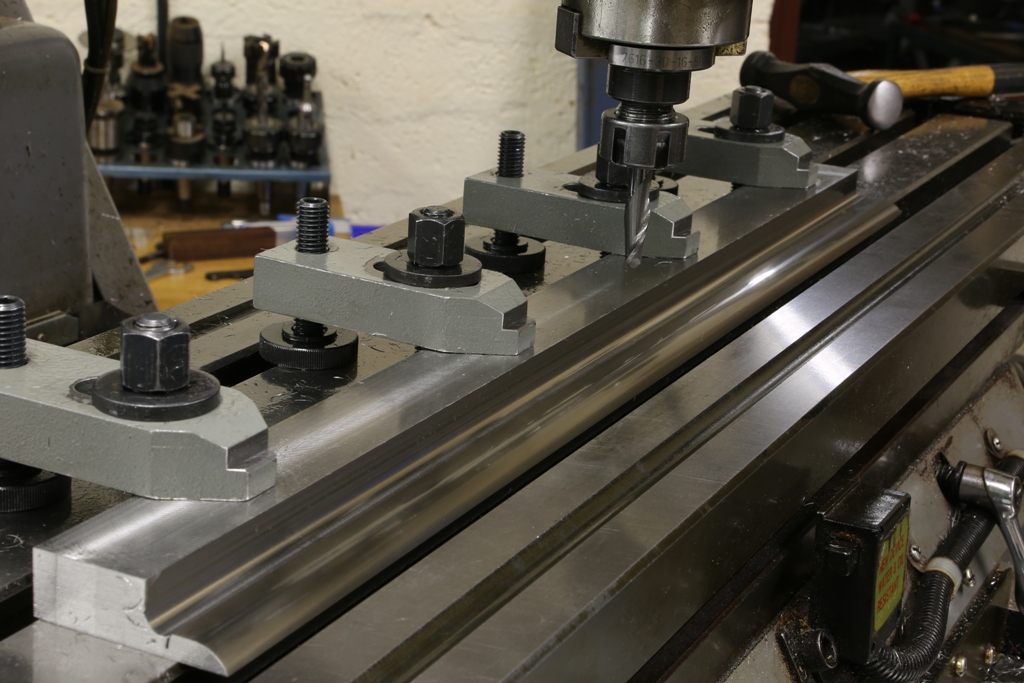

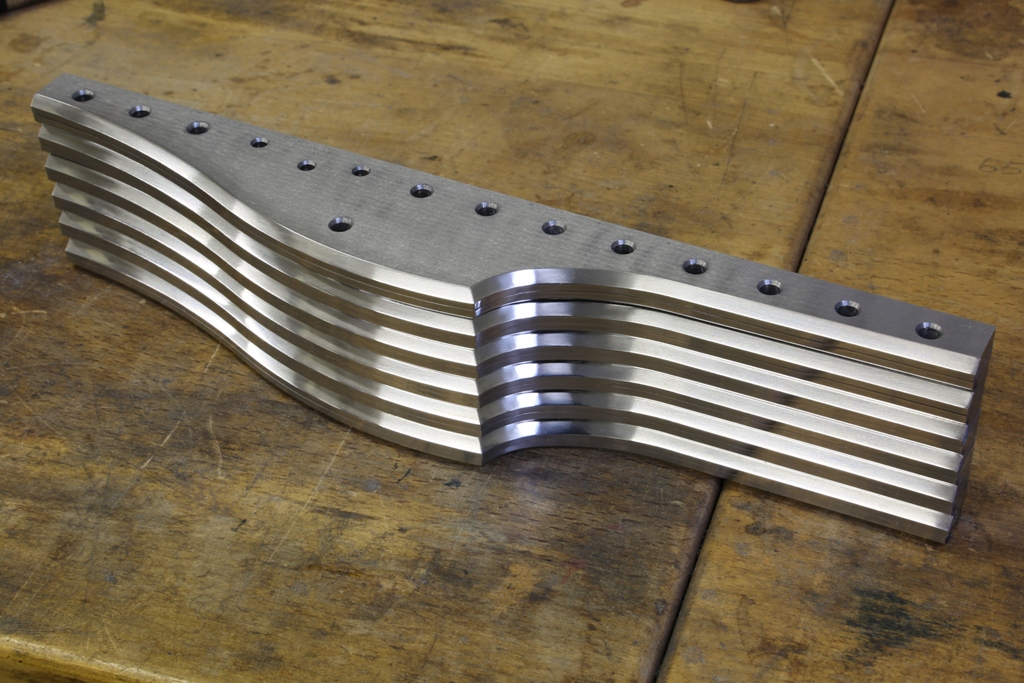

There used to be a time that I believed simple was easy – wrong. I certainly favour the simple lines. After much deliberation this union between the handle and sole works well. I am not going to show the whole plane until everything is finished.

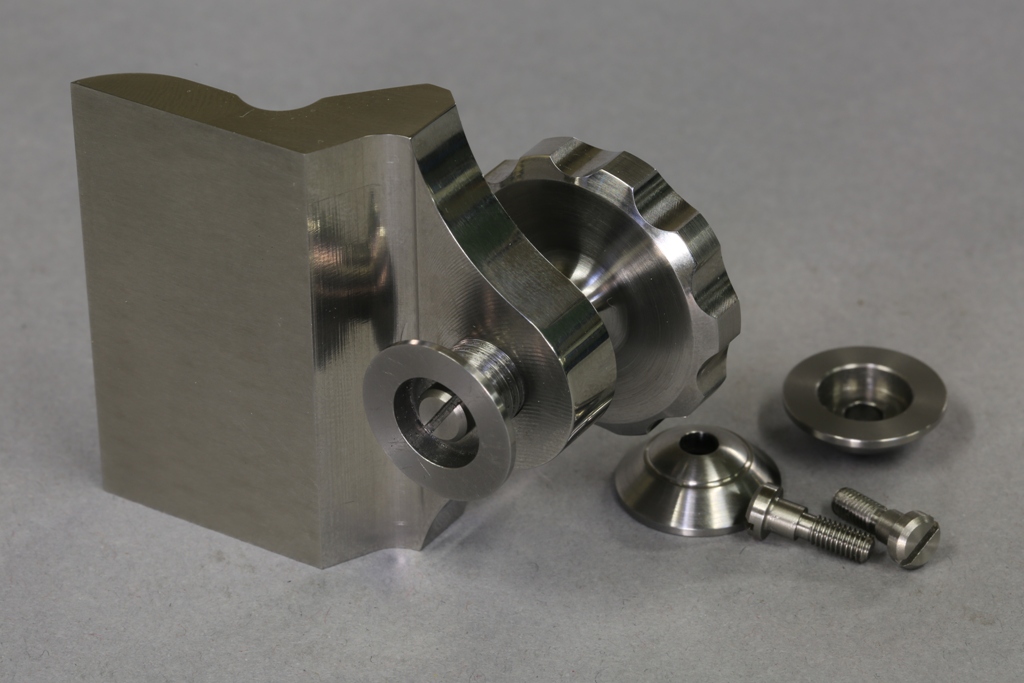

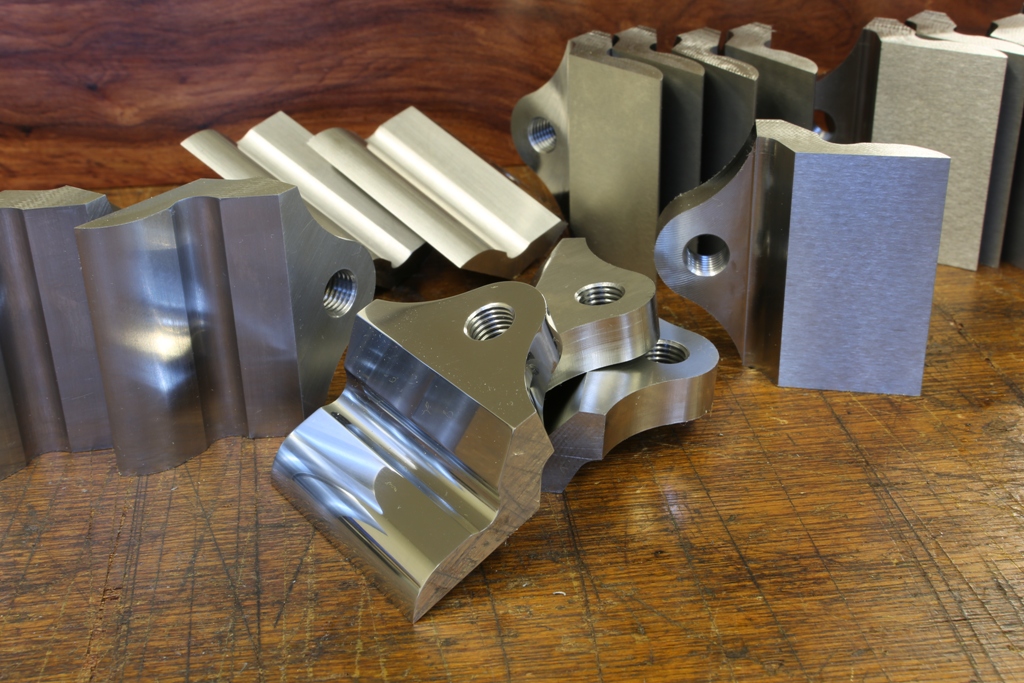

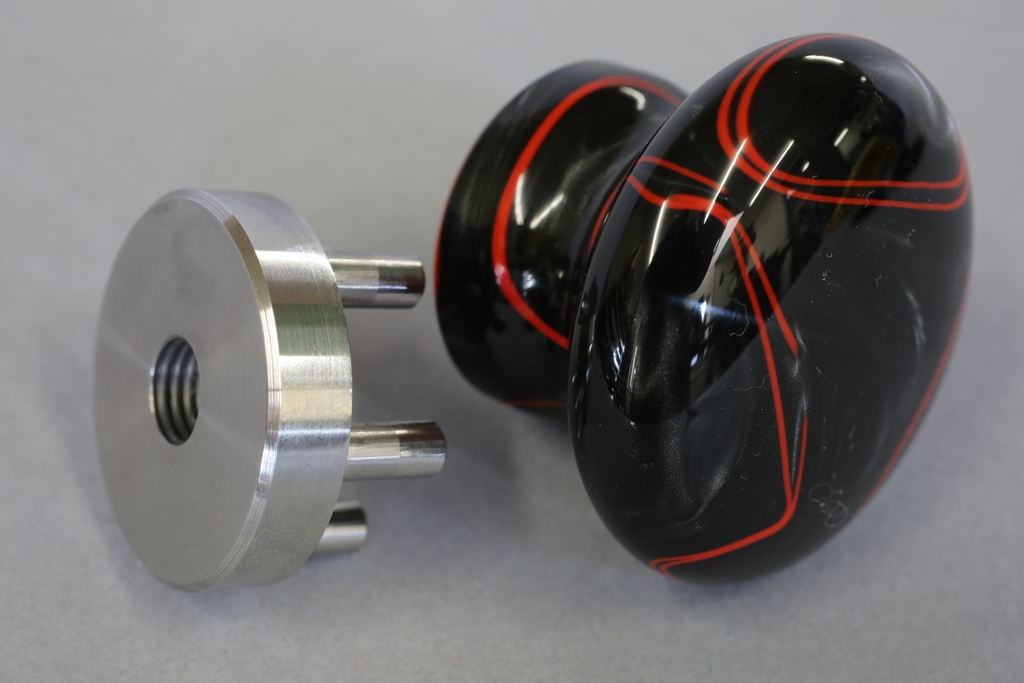

Here is the simple part….. Components are shown in pairs for viewing purposes.

These parts include handle boss, which has two 8 mm integral rivets which are peined into the sole. The boss body is to be recessed into the handle, drilled and tapped for the handle stem.

This stem is 10 mm in diameter at its base going down to 8 mm separated by the 8 mm hexagon. This is then secured with a wrench so it will always be tight at the base. This stem alone has a lot of rigidity to it which then compounds when compressing the handle.

The handle has a cup for its fixing nut. This fixing nut has a radiused slot milled into it so that it can be driven with a coin. The cup is faceted at the bottom so that it cannot rotate to avoid mismatching contour or come loose from the handle. This gives a very rigid handle which is compounded when the handle is tighten up.

All the components that you can see, including the screw cup, are made from solid stainless steel bar.

The boss and stem fixed in position.

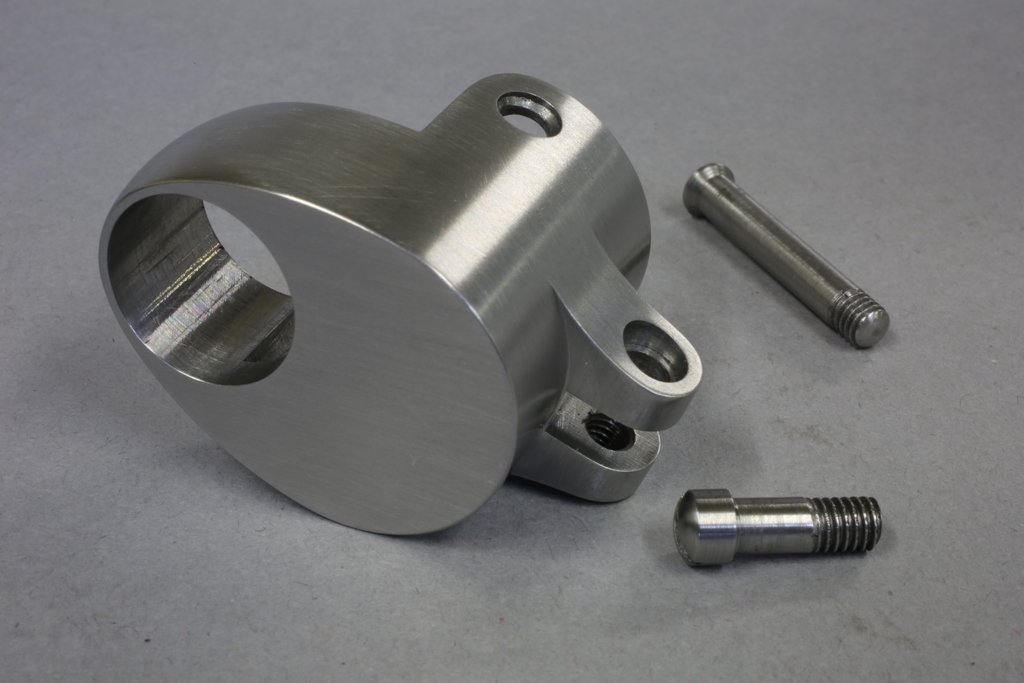

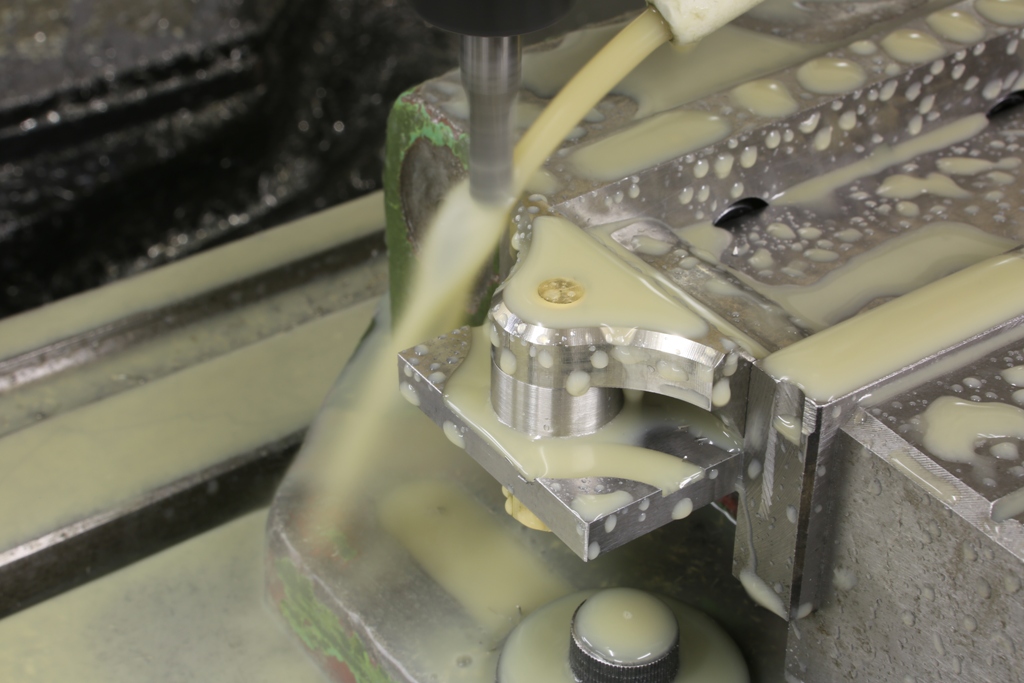

The adjuster – where does one start?

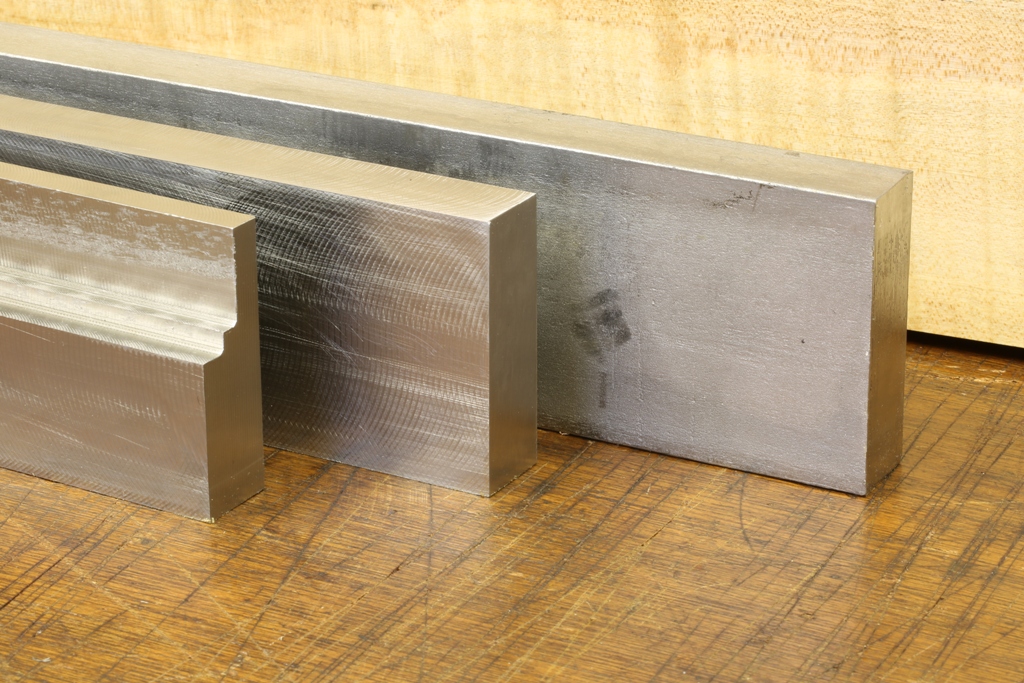

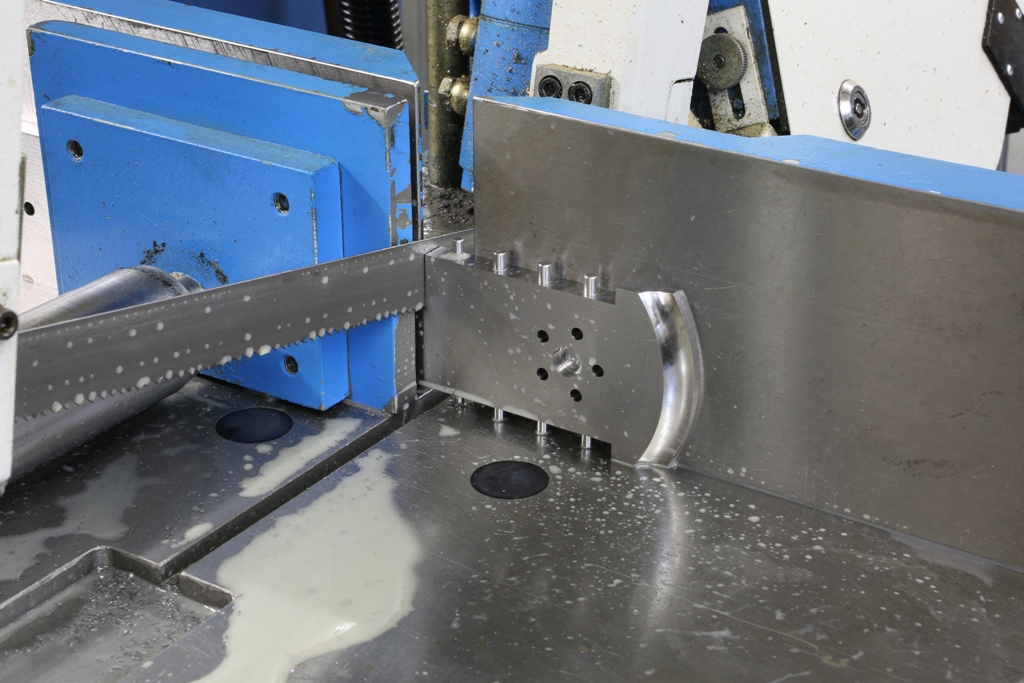

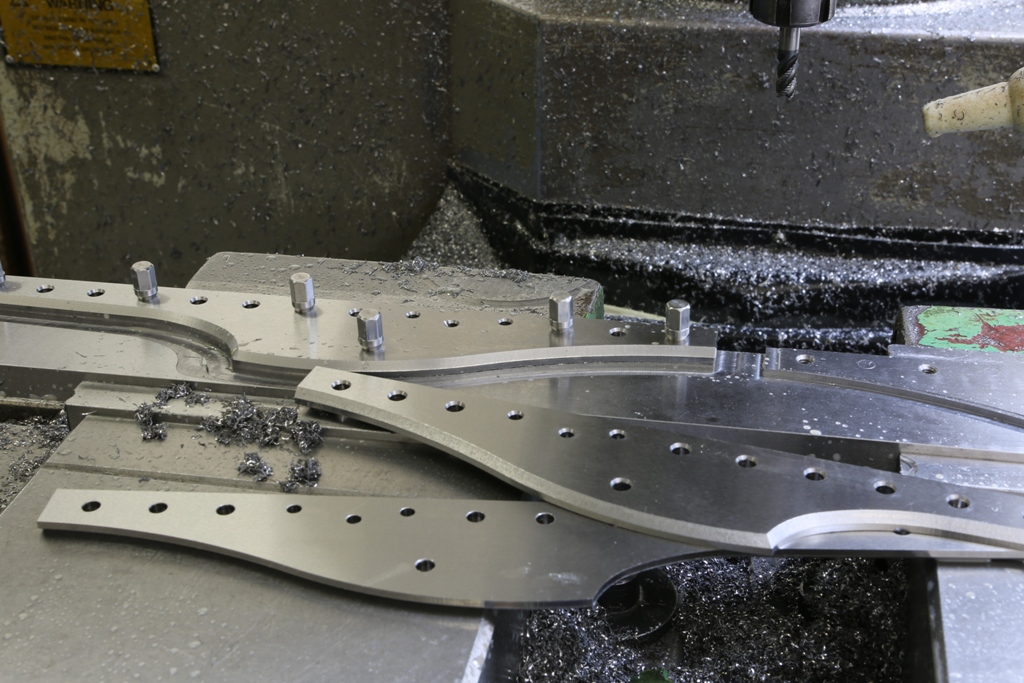

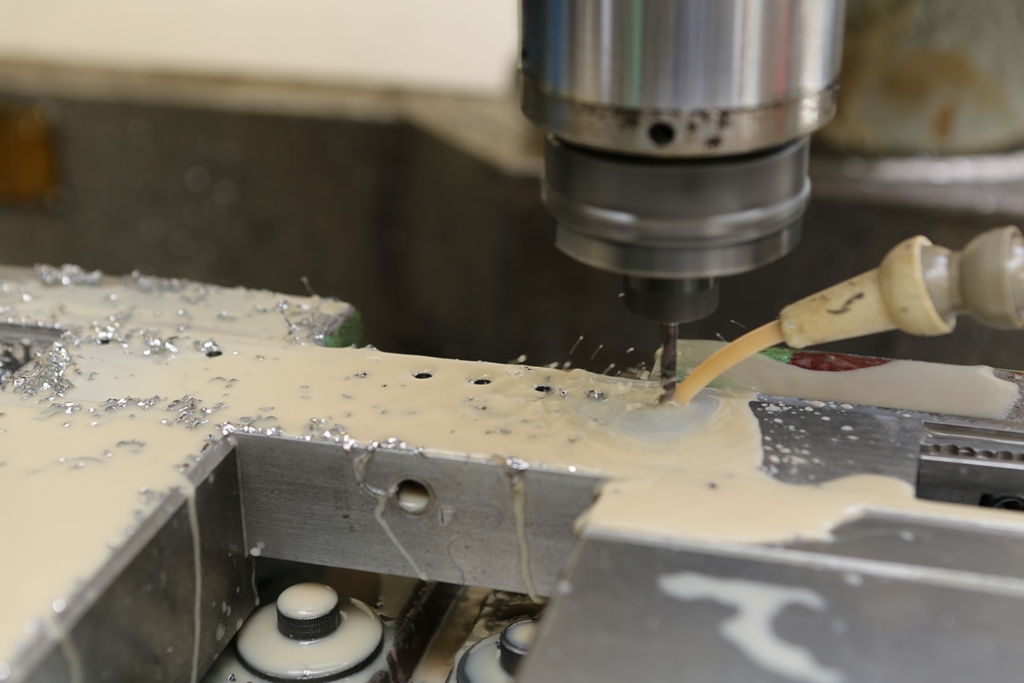

The most visual item is the spindle (still attached to its carrier) and like everything, it comes from a solid bar. It takes a lot of planning in the making. I will let the picture tell the story.

At the very last minute, when I am happy with everything else, the spindle can be parted from the carrier.

All the components are a project on their own.

A whole book compressed into a few lines ![]()