A photo of the infills before they go into their bodies. This Snakewood has had six coats of danish oil. As with previous work using Snakewood it hasn’t cracked whilst building up the danish oil. It does look a bit good.

June 9, 2017

May 19, 2017

Window to my workshop 112

I have seen my work described in forums as analytical and lacking the warmth of a more rustic finish. However, my personal taste is perfection.

To achieve this perfection on the adjusters for my planes, work is intensive and the inletting for them is also time consuming. The system I use is on the CNC milling machine as the quality of work is essential. It is important to have an uninterrupted feed rate using state of the art tungsten carbide tools. This I think is more desirable than a hole that looks like it has been gnawed by a rodent ![]()

April 24, 2017

April 20, 2017

Window to my workshop 110

I have been wondering what to with my stock of snake wood, as you can only use it in small pieces. It seemed fitting to use it on these last A31 Thumb planes. This picture shows the nature of the wood after preparation, it will darken down to a nice brown. It has always been a favourite for knife makers and for pistol handle scales.

April 13, 2017

Welcome to my workshop 109

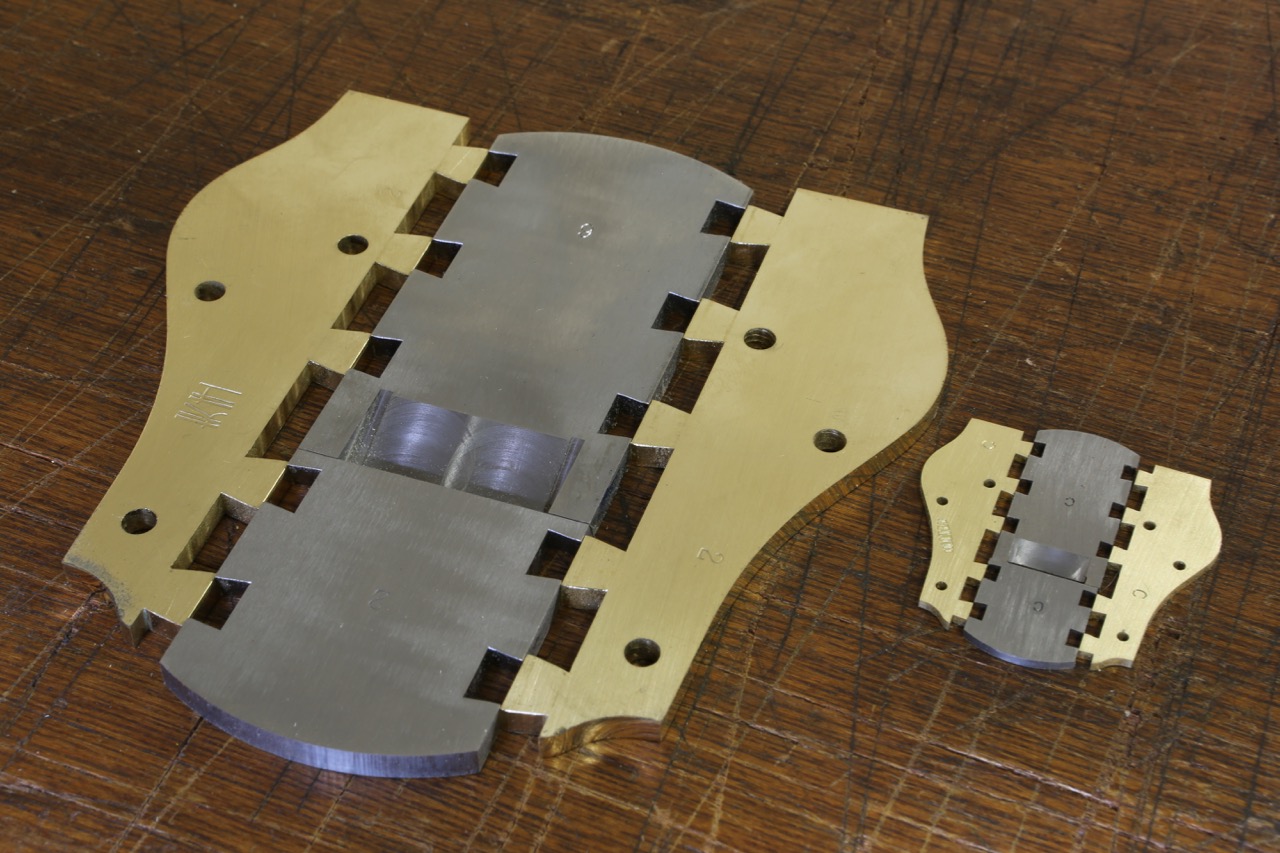

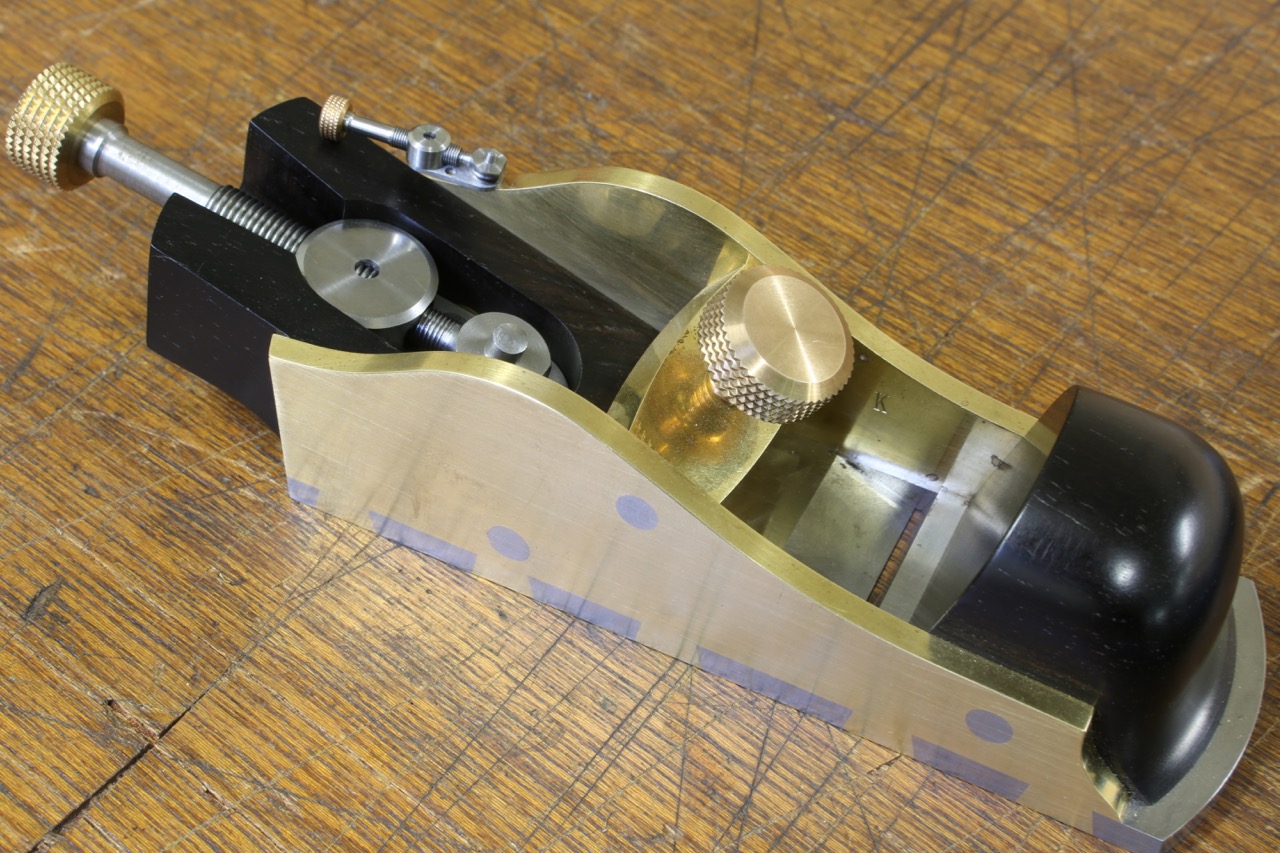

It is rare to get the components from both planes together – full size and one third size. The work is still the same. Despite all the years I have been making these planes I forget the amount of work involved.

April 12, 2017

Window to my workshop 108

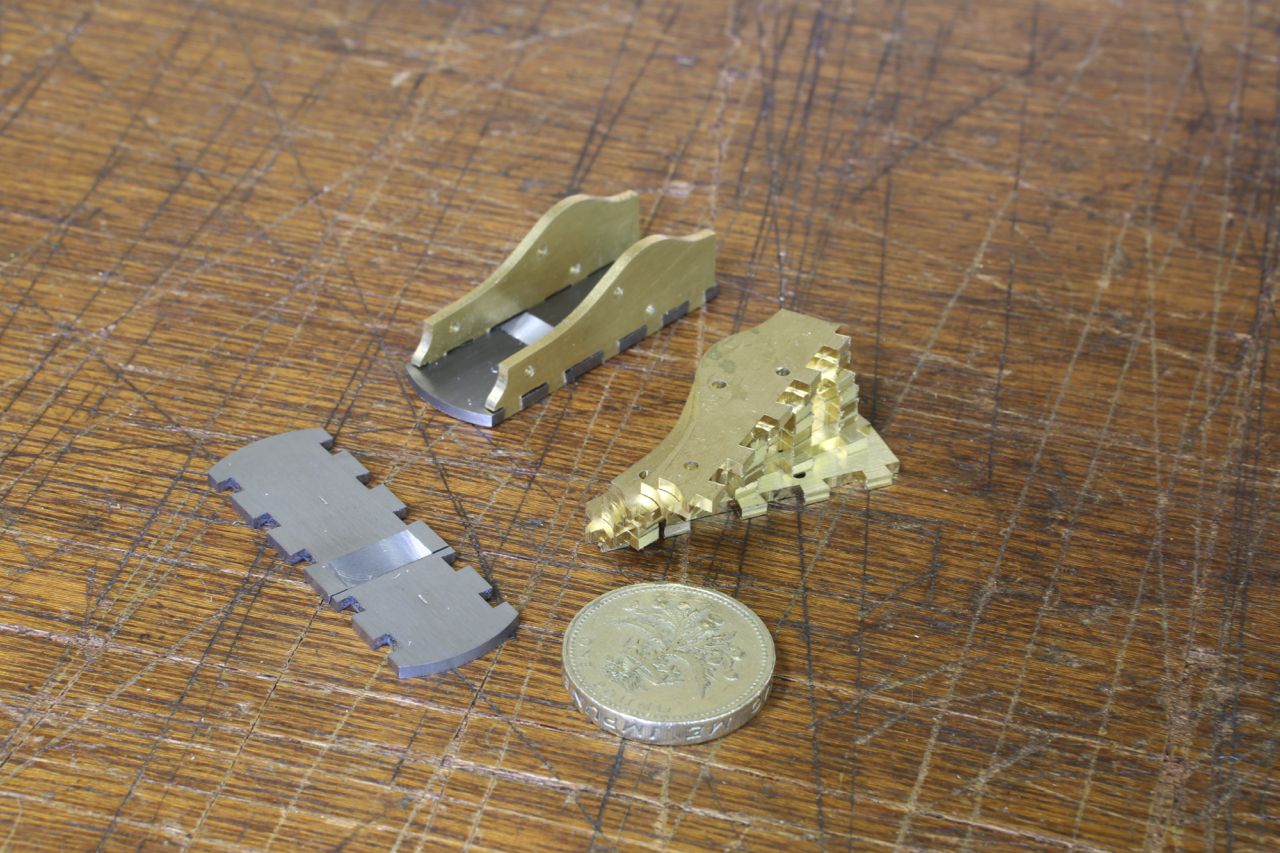

I have had some A31 miniature components stored away for some years, but this did not include the brass sides. With a commitment to build a few full size A31 planes it seemed a good idea at the time, to include these miniatures. If not done now they will never be made. It seems quite remarkable that I have laboured over so many components and acquired so much stock it would be a shame to abandon it. I have nightmares about all those hours never paid for ![]() A lot of these components were made before I started blogging. It is a difficult job to convince people that the price does not scale down so I will try and show the story here. More to follow.

A lot of these components were made before I started blogging. It is a difficult job to convince people that the price does not scale down so I will try and show the story here. More to follow.

April 5, 2017

Window to my workshop 107

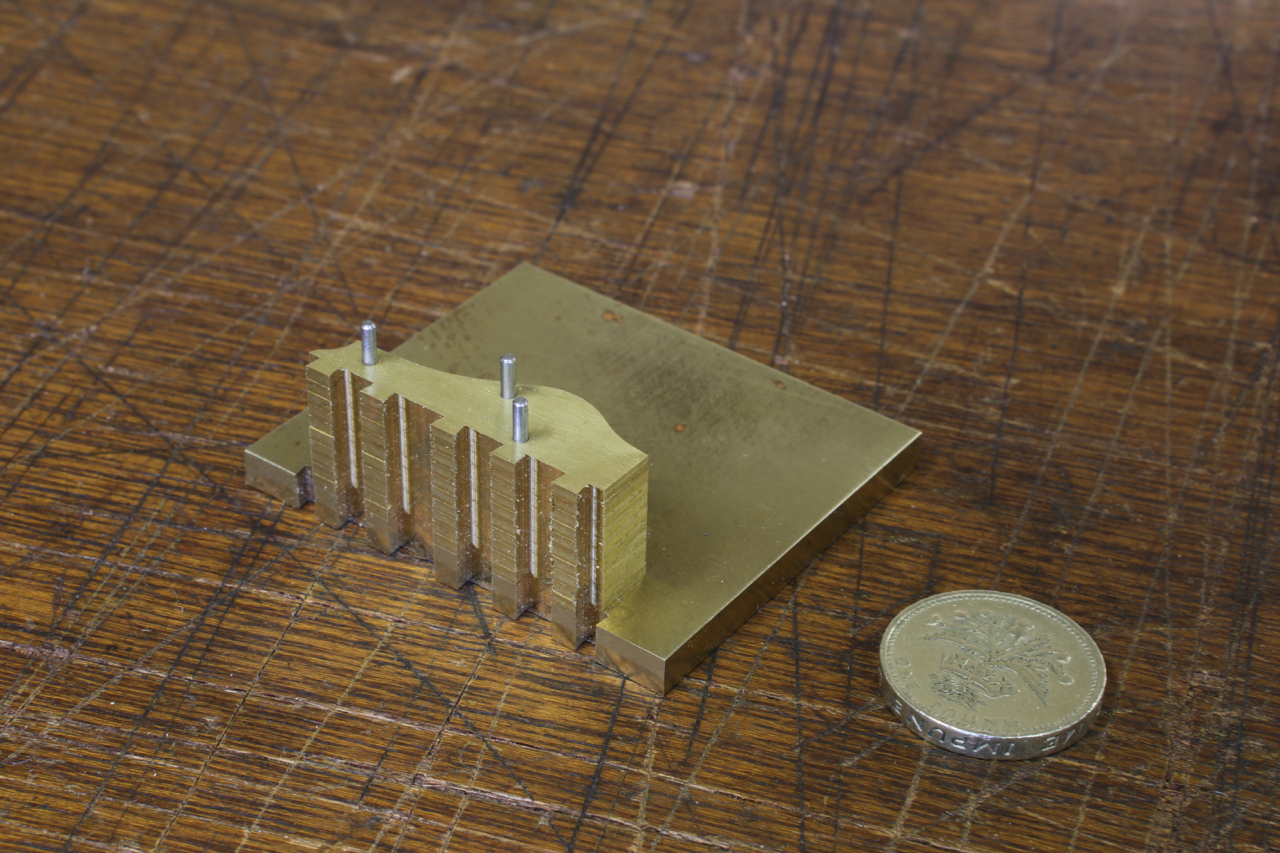

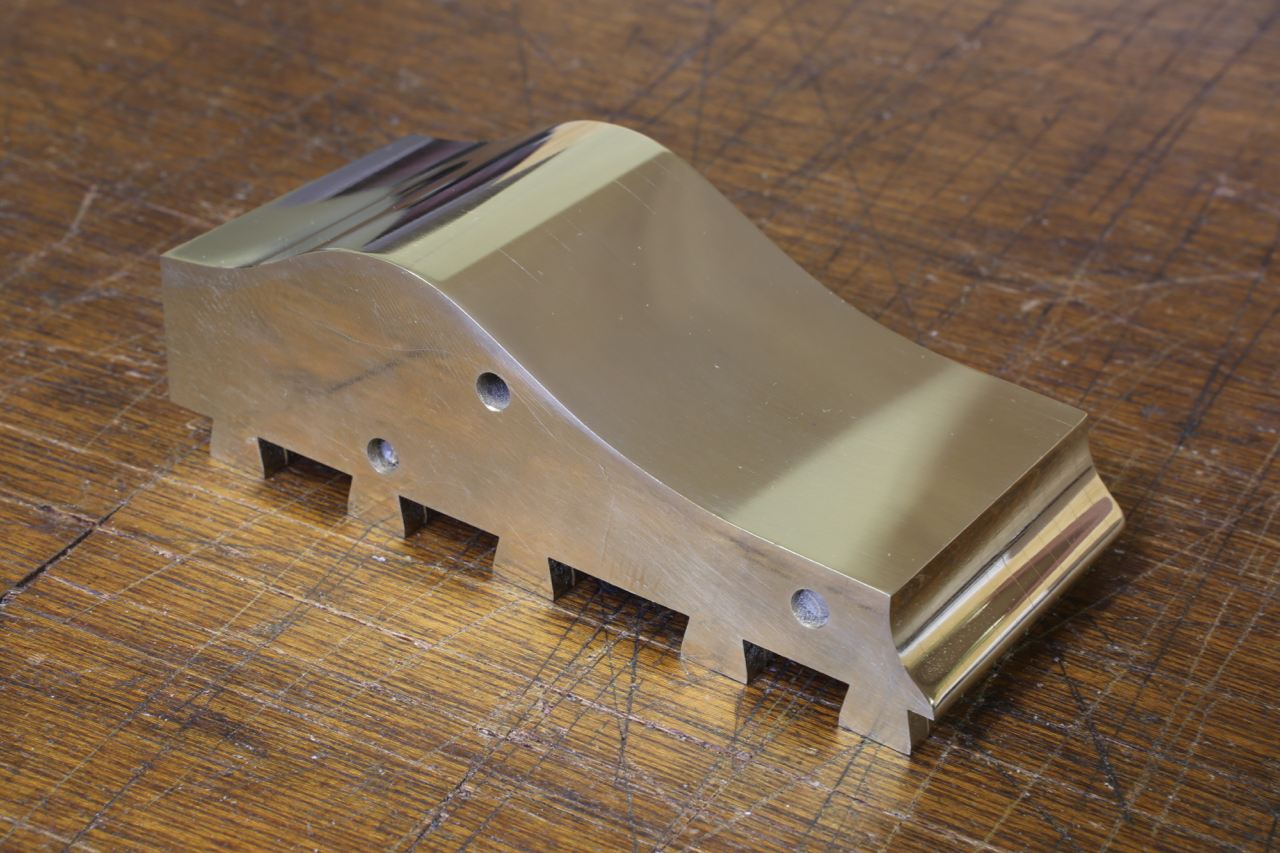

Edge polishing to the sides is usually done with all the sides in a block to keep all the edges true and square.

All my hand work it has to be as good as the machine work, at the risk of looking clinical with no soul ![]()

March 31, 2017

Window to my workshop 106

During the course of the completion of these two A31 planes – full size and 1/3rd size – I will be posting up comparison photos over the next two months.

It is always amazing to see how small the 1/3rd size plane is.

June 8, 2016

Window to my Workshop 105

With all my component parts finished I was just left with some wooden handles which should have been finished off earlier as they need to be oiled and cured.

It seems an opportunity to show that there is a lot of hand work in my planes.

Now there is the fitting, milling, grinding and final tweaking. So Claire had better get those baize bags done.

Thought I would mention that the riffler I am using here is one of Noel Liogier’s. It is probably about the only one I have come across that can handle these exotic hard woods without getting tired. In fact it is so efficient that I am having to learn not to be so heavy handed. I would really recommend these rifflers because I have always had a problem with shaping some of these hard exotic woods. The double ended rifflers were given to me when I was exhibiting in Munich in 1998 by Zoltanne Nagy – they have served me very well but unfortunately I can’t find anymore to replace them. Noel’s are supplied with fitted handles.

June 3, 2016

Window to my Workshop 104

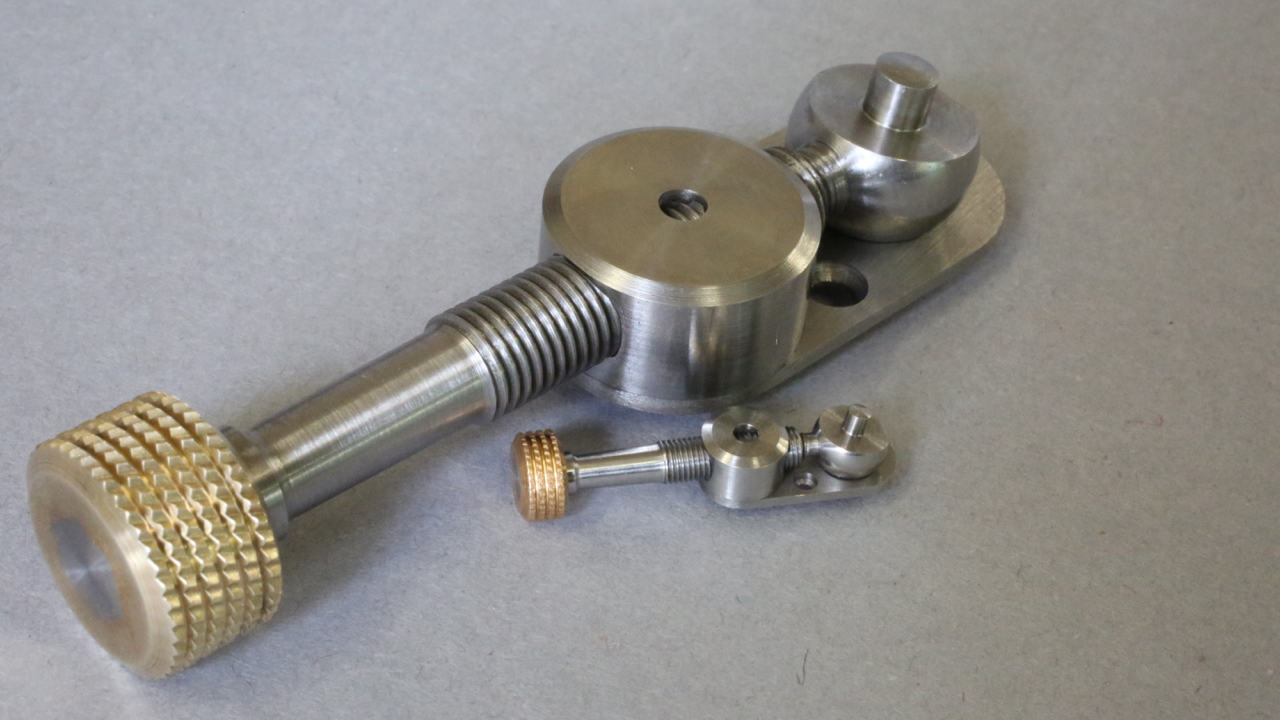

I had hoped to use the adjuster components from the No 983, as I showed in the last blog. However, I wasn’t quite happy using them in this application. We all know what that means – I started again. This has cost me another two weeks.

I had to make a dedicated holding fixture for both lathe and mill. Part of the work on the spindle is individually paired with it’s traveler part keeping the end play down to less than a thou.

Of course there will be some end play in the threads of the main spindle. I work on every component to keep this end play down to a minimum.

This now concludes all the metal parts. I have wooden totes to finish off, will blog these later. There should be completed planes by the end of next week.