Another picture which I missed out yesterday

September 18, 2019

September 17, 2019

Workshop blog no 30 – No 985

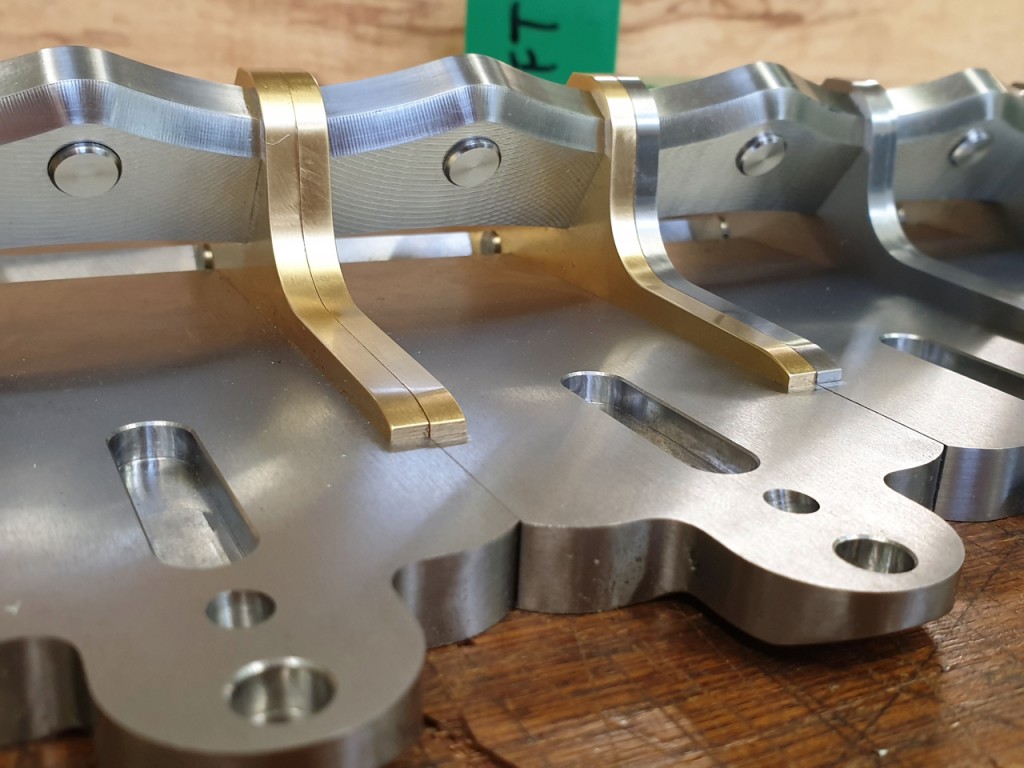

Photos showing the bolts trimmed, milled and surface ground. This plane has probably been the best of all my work and one of the most important factors is the much heavier chassis. I have been able to work to very much tighter milling tolerances, in fact well under 1 thou. It has helped on the grinding because I need to take less off – stainless steel is very difficult for grinding and I can only take cuts of .0002″ (that is 2/10 of a thou). The more cuts you take from stainless the harder the material becomes. You also have to be continually wheel dressing even with using a ceramic wheel. This is the real work that I enjoy the most.

September 14, 2019

Workshop Blog no 29 – No 985

The bolts have been thread locked with Loctite 270, so things should be moving along very quickly now.

August 24, 2019

August 18, 2019

Workshop Blog 27 – No 985

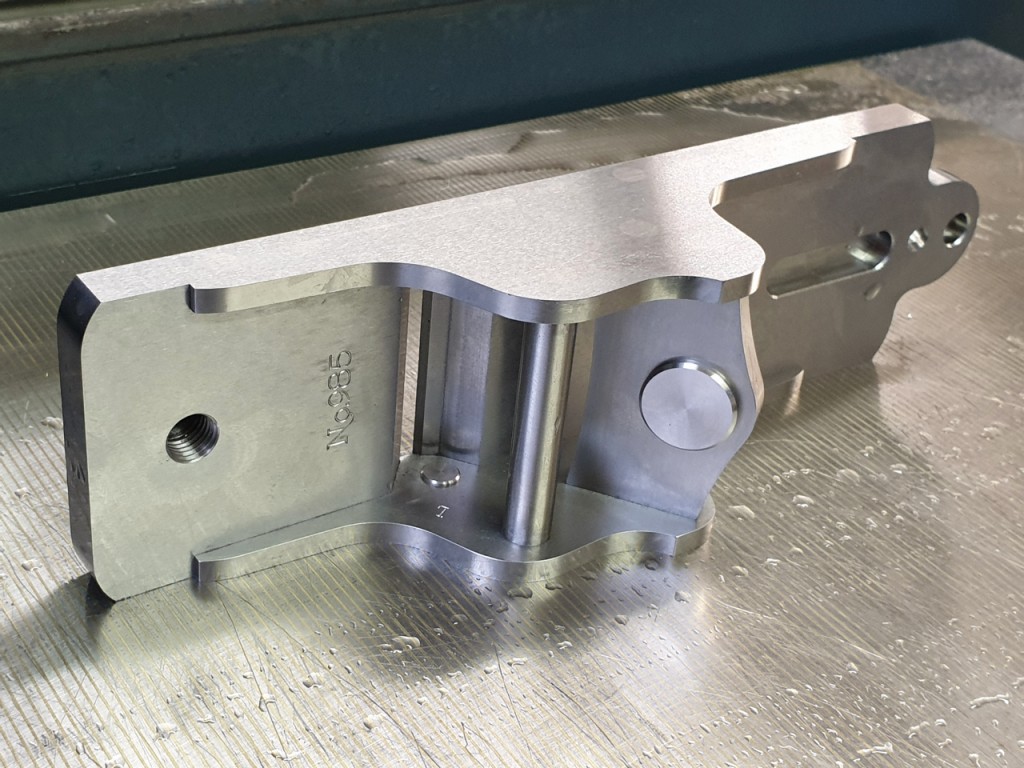

Just thought I would put this picture up of the No 985 smoother in its chrysalis form, still some work to go but on course to be completed for the end of the month.

June 17, 2019

Possible new project

Unable to sleep last night as often happens, memories were going round my head. I have been asked by violin makers if I would make a set of finger planes. I have said yes several times, but it has just gone in the pile of promises. It is interesting to know if there is enough interest in these planes. The one photographed here would serve as a template, allowing for design adjustments for size. It would be my idea to start small and work my way up the scale over a period of time to allow for people to recover from the price. There are plenty of these planes out there but I haven’t seen any quality ones. This ESE captured my attention.

June 7, 2019

Workshop Blog 26 – No 985

dalbergia stevensonii better known as Honduran Rosewood

Over the years using various selected rosewoods this one has captivated me the most. It is not a bling wood, but it has an attraction of its own. It is very tough and business like. The contrast does not fade like many of the others. It takes an oil very well. No matter how plain it may look there is a hidden beauty that reveals itself quite quickly once you start shaping and fine finishing. This is an area where I find a lot of satisfaction and reward for all the effort that goes into the work. There is one downside to all rosewoods – I have an allergy to it. This Honduran one used to be the least offensive but after many hours of work it has turned on me.

This handle represents the end of the bunch and where only hand finishing counts.

June 3, 2019

Workshop Blog 25 – No 985

Still plodding along.

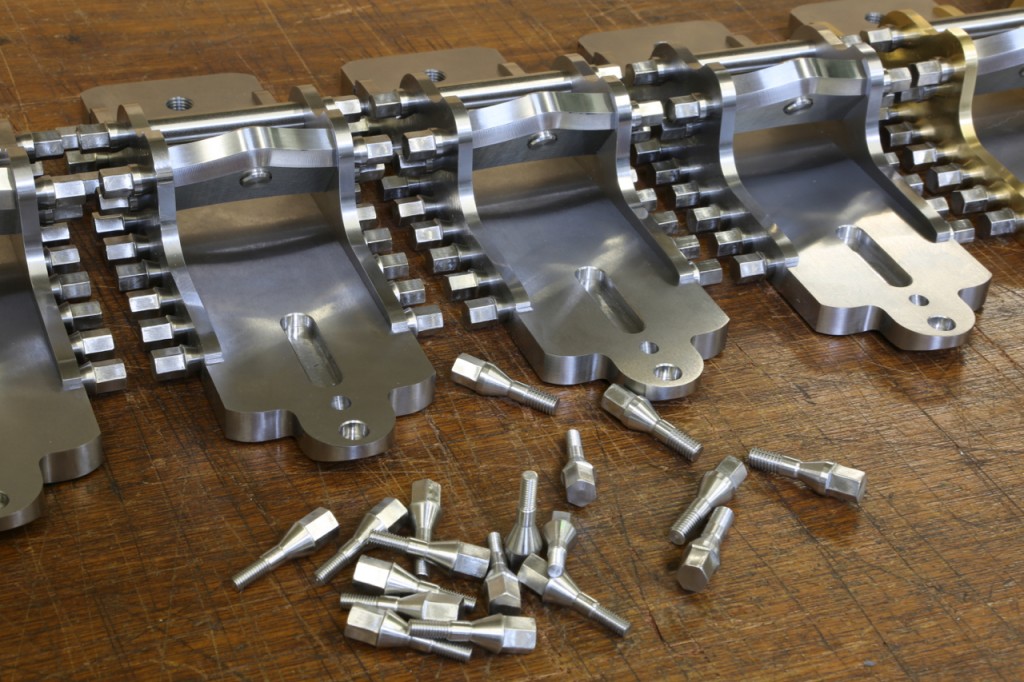

The first picture is to try and give you some idea of the work that goes into these planes. The picture should be self explanatory. It shows some of the metal (stainless) work and handles. From this you can see it includes spines that are threaded and keyed ready for cementing with epoxy into the handles. This gives the kind of strength and rigidity which would surpass what is normally found on a closed handle.

It is this kind of work that makes me one of life’s misfits.

Now I am on to the handle shaping which is basic hand work. My CNC machine doesn’t seem to have a button for this job. I find pleasure in the wood taking shape and interesting contrasts come to life.

Here the chosen wood is a Honduras Rosewood – Dalbergia stevensonii – still lots of work to be done. The price of the plane goes up and up with the pain of the work.

May 23, 2019

Workshop Blog No 24 – No 985

Slipping behind on postings as I have been so busy.

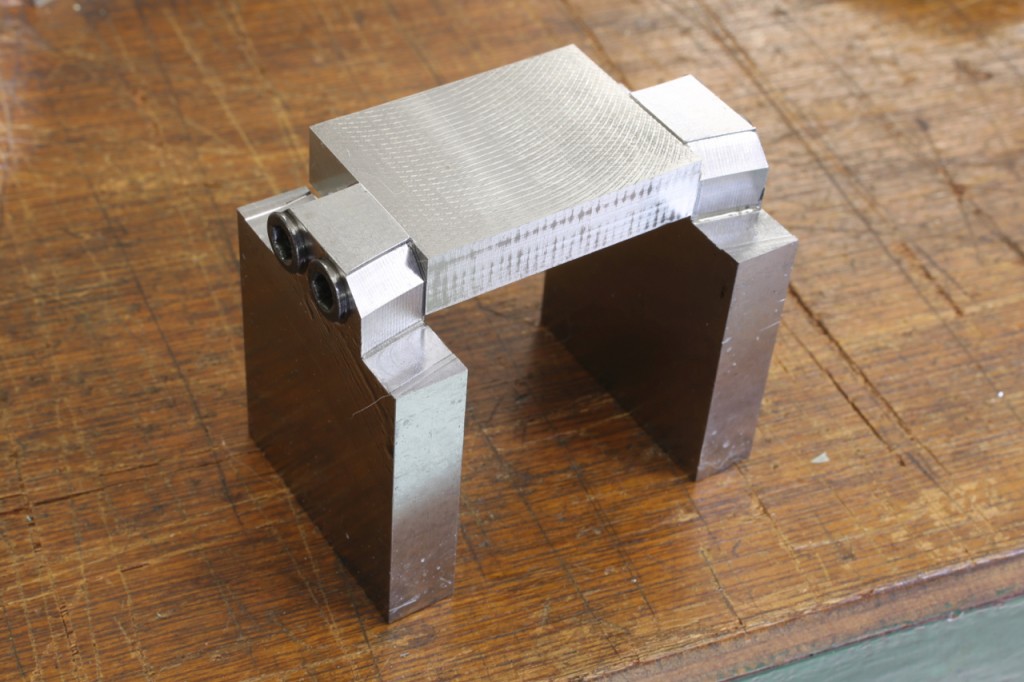

As a follow on from last posting on upper blade bed, the design is similar to the one used in my No 982. I didn’t want to go this far but I can’t think of anything better. It is certainly solid if nothing else. You just have to bite the bullet and get the work done.

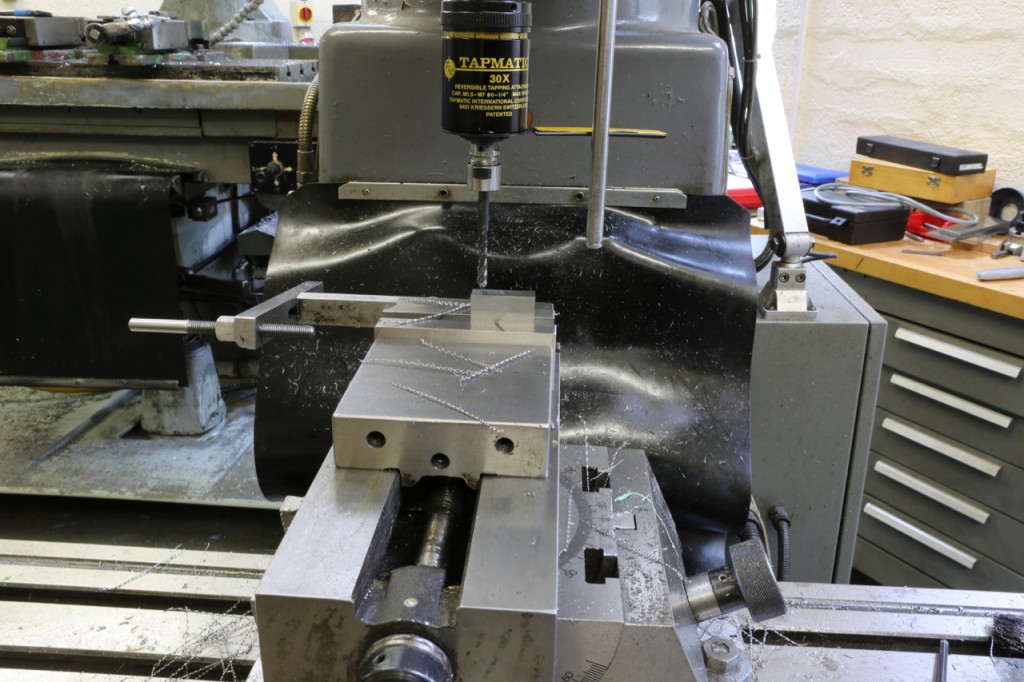

This picture shows the tooling required for the last part of the operation after much preparation. As you can see this kind of tooling doesn’t come cheap. I always keep plenty of backup – if I get a tool failure I want to be able to change it immediately.

May 8, 2019

Workshop blog no 23 – No 985

Looking back on the last posting and it has been a whole month – I have been away for a while and life just seems to get in the way of work sometimes. Was having a look at what retirement could be like, but I can’t afford it!

A quick photo of work on the upper blade bed. The amount of work here was greatly underestimated in my planning. It is always difficult to estimate in the first place and then I keep tweaking and tuning as I go along. Why spoil the ship for a ha’porth of tar. I don’t think I will ever be rich but I can aim to be the best.

I will retain radio silence for a little bit longer until I have something more interesting to show.