July 22, 2013

July 17, 2013

Window to my workshop – 69

June 26, 2013

June 14, 2013

Window to my workshop 67 – No 983

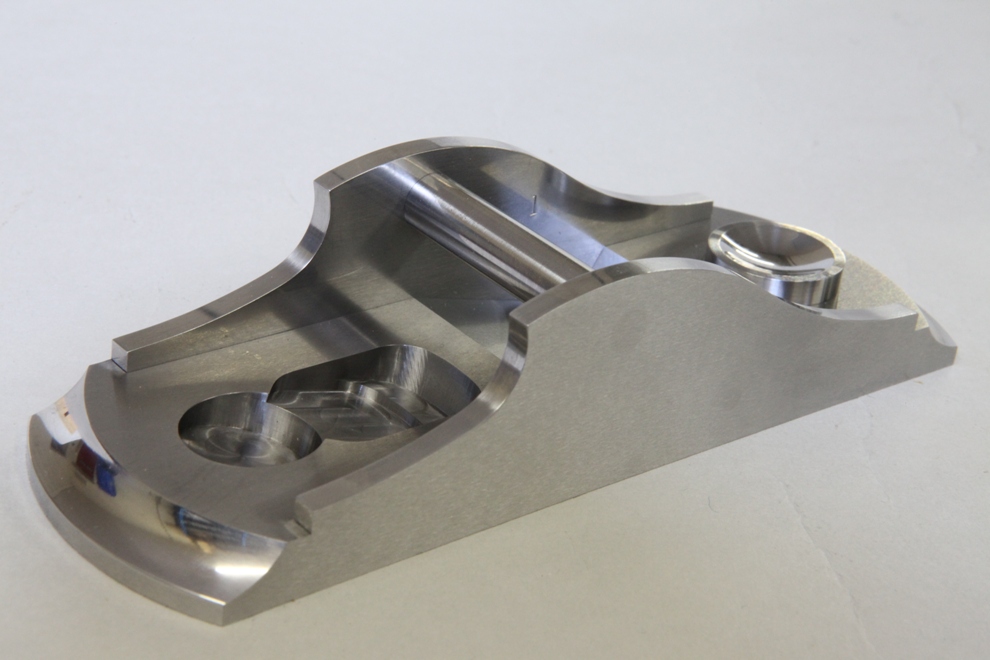

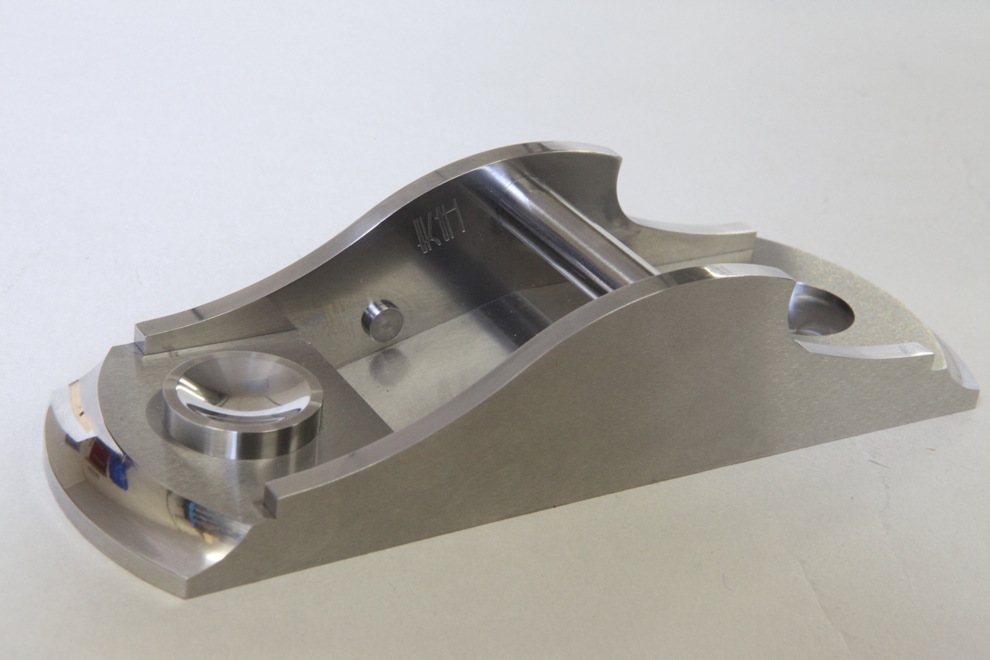

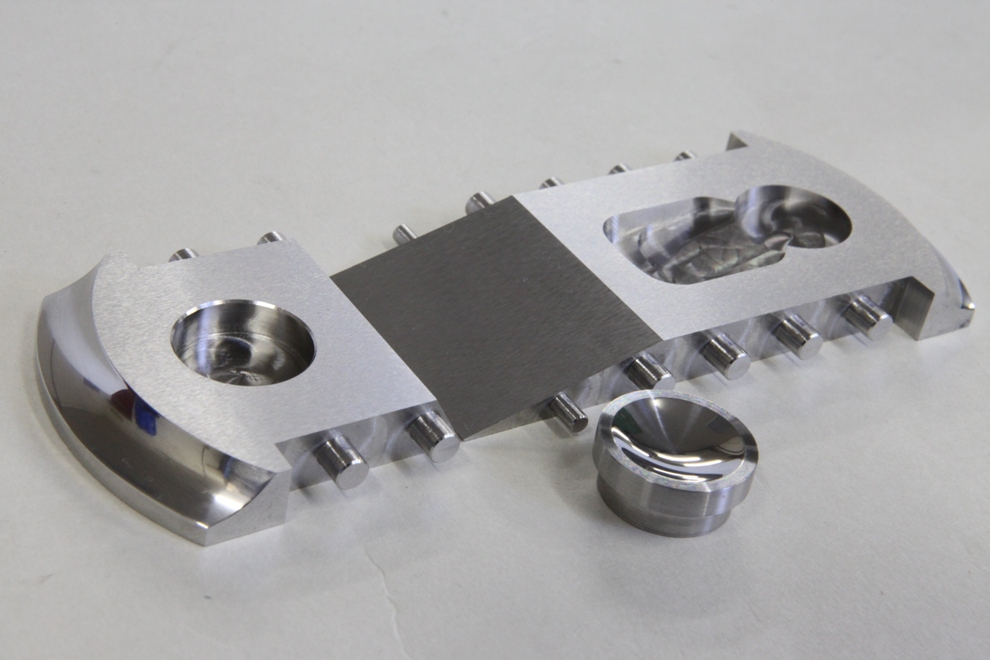

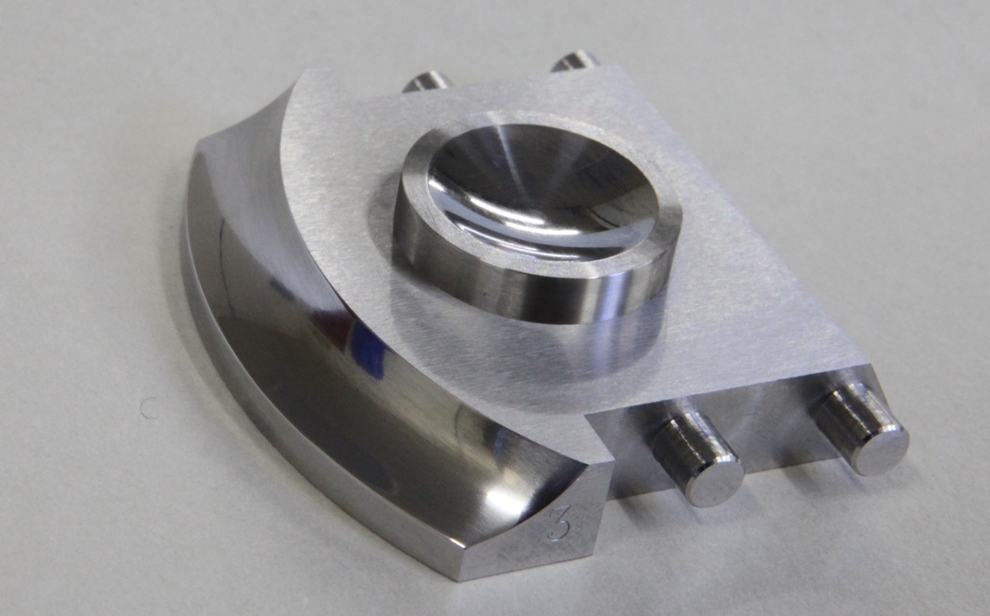

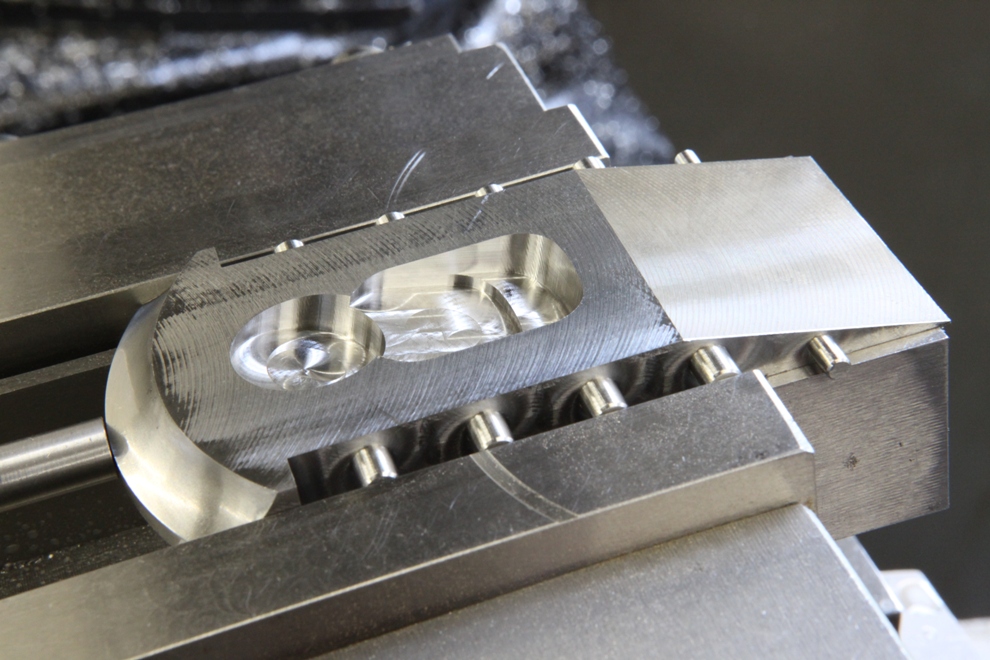

Work in progress on the new No 983 stainless steel block plane

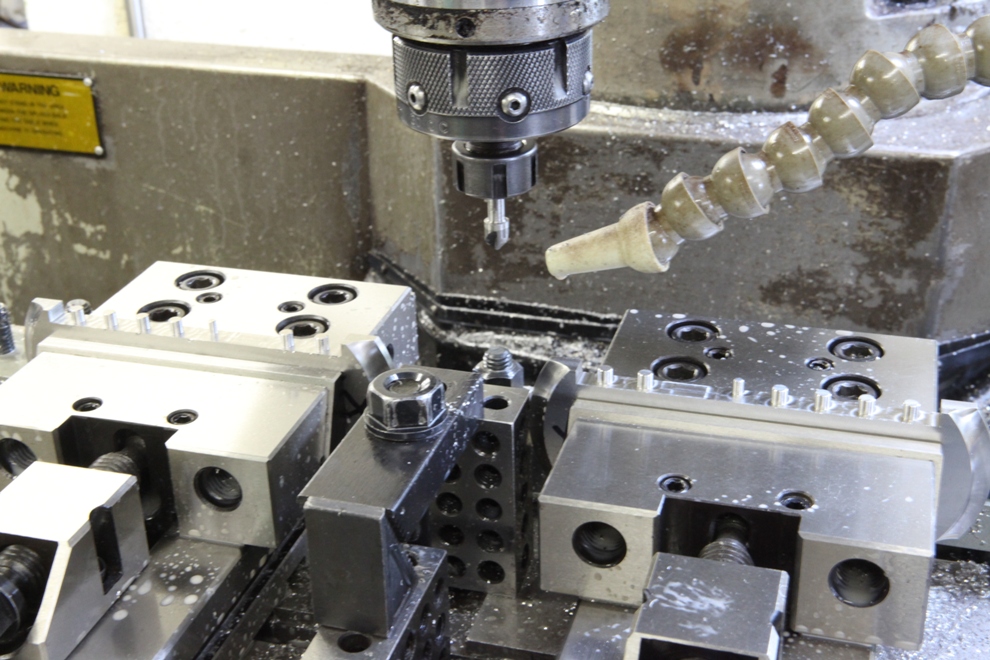

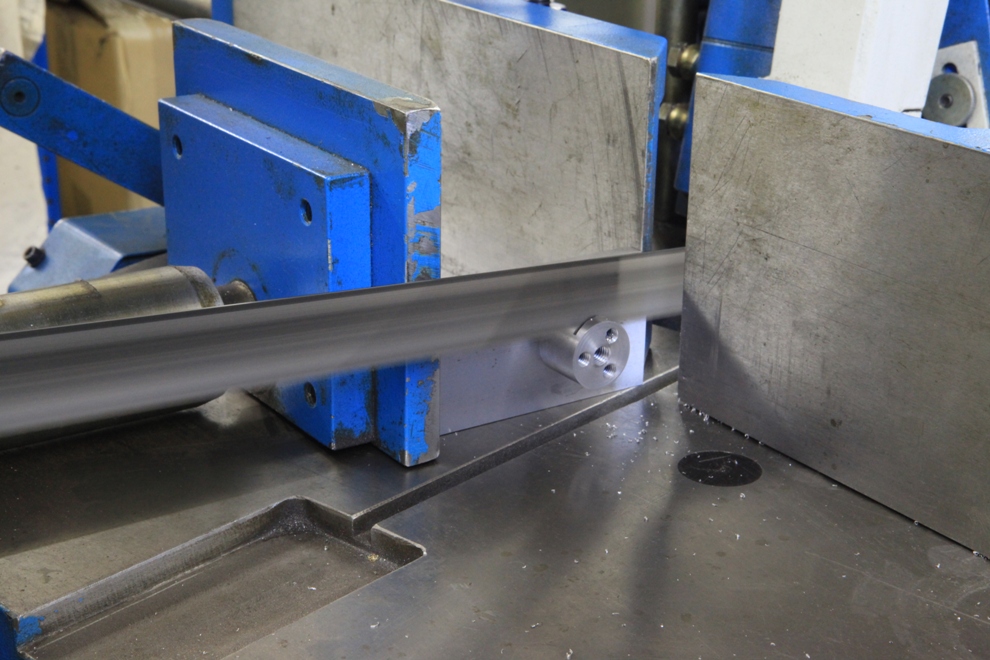

Integral pins are back! These pins are cut 0.22″ long, cut full depth in one go with a 6mm roughing cutter. Then go round the houses again with a 6mm finishing cutter. Some people don’t believe that I can cut these pins full depth in one go in s/s (or any other material). It is just a matter of getting things right.

The last job is to put a tiny lead chamfer which not only makes an easier entry but it helps to prevent the edges from splitting during the peining process.

February 6, 2013

Window to my Workshop 66

I thought it about time I wrote some more in my blog. Looking back on my past entries I notice that there are some gaps which I intend filling here.

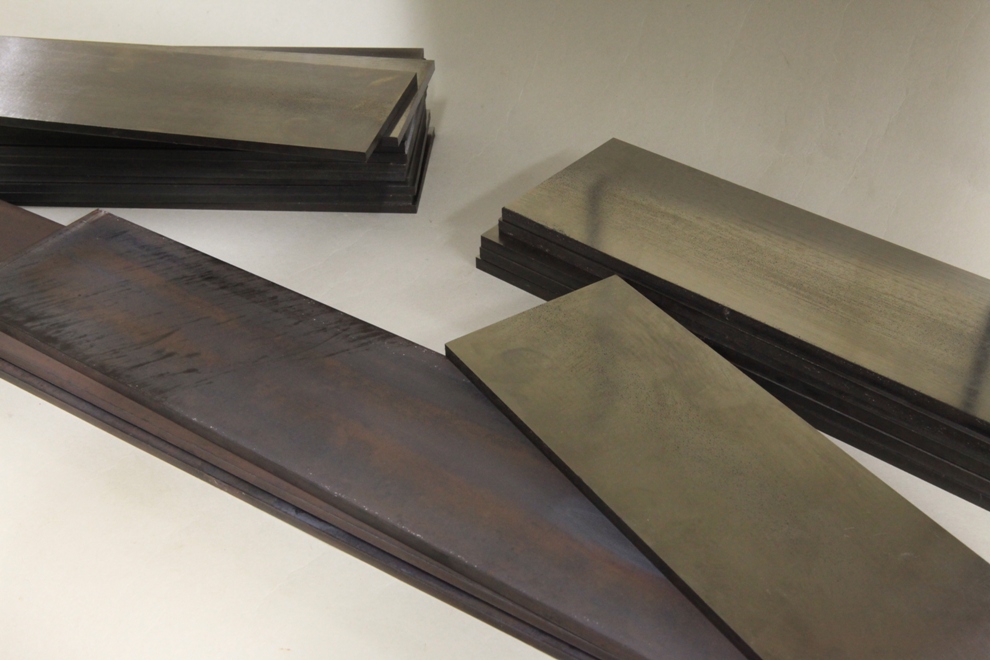

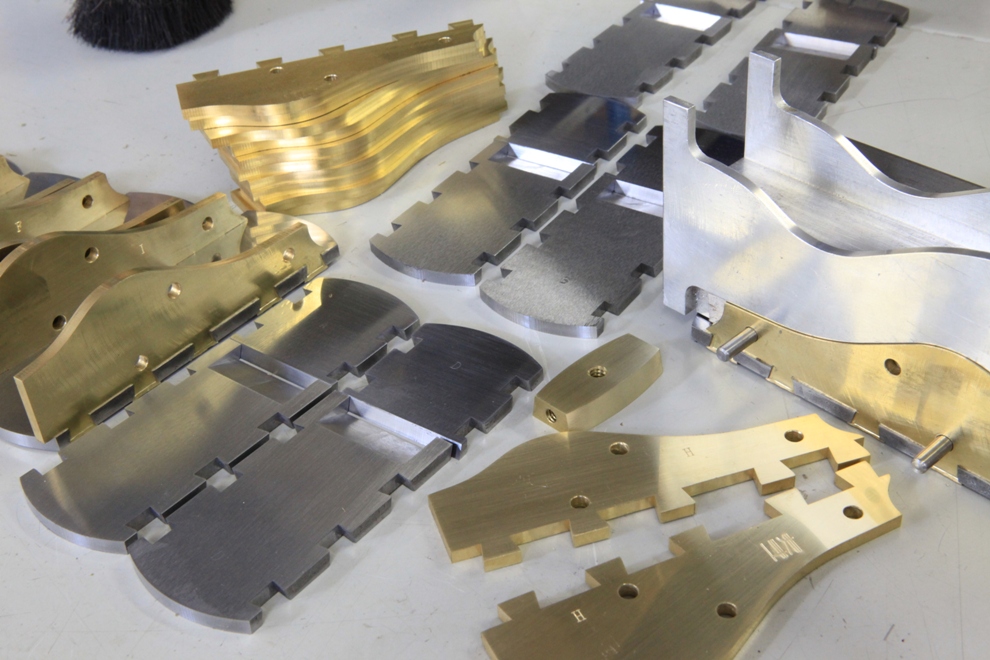

At the beginning of any project the metal is a good place to start (after design and drawings are done of course). In all my classic designs I use mild steel – I have tried it in several different forms; hot rolled (which is very good and has little stress in but comes with a lot of scale to deal with), BMS (which is nice and clean but has a lot of stress in it), sheet metal (which still has a difficult scale to deal with and some stress). Stainless steel would be my favourite choice, but not on the classic type of planes. I therefore choose mild steel as this is a nice ductile material once the stress problems have been dealt with. To relief the stress I have to cut it to manageable sizes and send it off for heat treatment. This picture shows the material in two stages – after heat treatment and some after surface grinding.

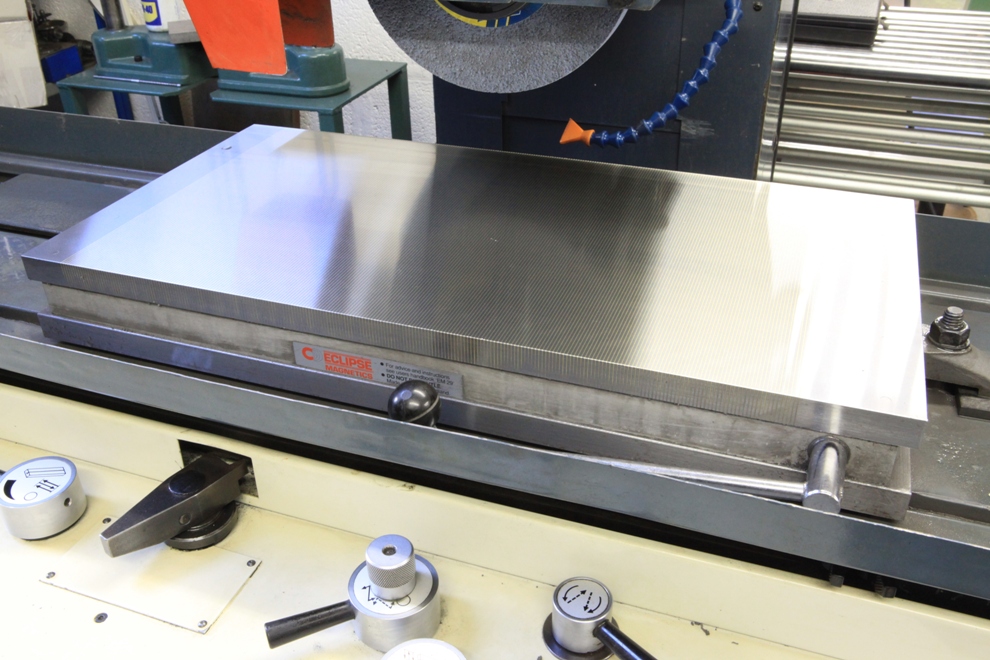

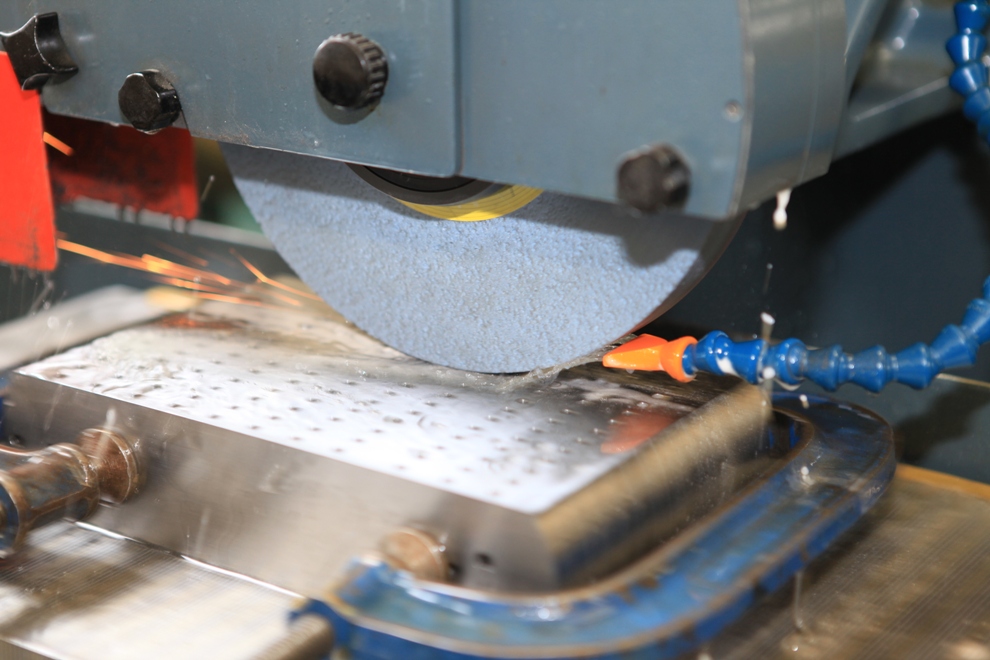

As you can see from the picture my grinding machine is a Jones and Shipman 1430. It was made in the ‘60s and it has been reconditioned by Andmar who are more ‘Jones and Shipman’ than the company themselves. It has been the main stay of my workshop since I purchased it 10 years ago as all my work including tool making passes through here. That is every jig and every piece of work holding (as well as plane components). It sets the standard for all my work.

This surface grinder uses a 24” x 12” Eclipse magnetic chuck which needs re-surfacing every 12 months. This can take up the best part of a day. The nice true surface is so good I just had to photograph it (sad isn’t it!).

My current project is A1 14 ½” Panel planes. I have documented this before (use this link http://www.toolworkshop.co.uk/blogarchive/) so I am just putting a few pictures to look at.

November 8, 2012

Window to my workshop 65

These Thumb planes are now finished but I didn’t have time to blog it. However the techniques are the same as on all my other planes.

They are available in Cocobolo, African Black Wood and Boxwood at £3,750 (+ vat if applicable).

September 5, 2012

New Project – A31 Thumb plane

May 11, 2012

Window to my Workshop 64

Continuation of the last batch of No 982 planes

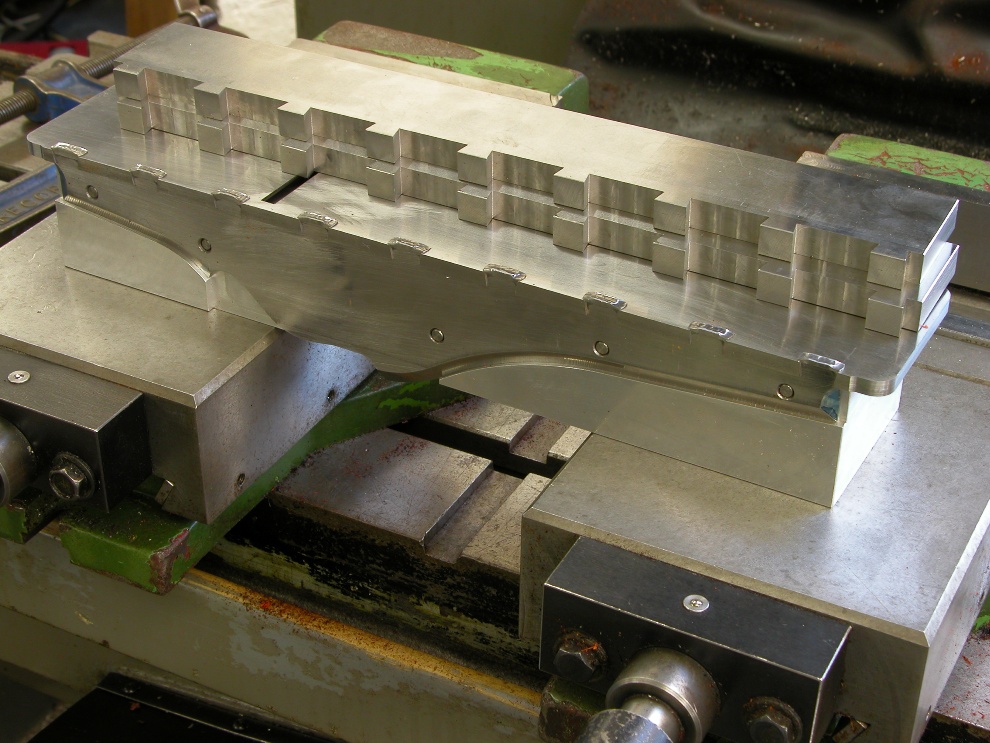

There are two reasons that I use the surface grinder a lot; the main one is for the precision and also for the nice textured finish. This usually means that I visit the surface grinder several times during the working of the plane as no matter how careful I handle the work pieces they seem to break out in a ‘workshop’ rash very quickly.

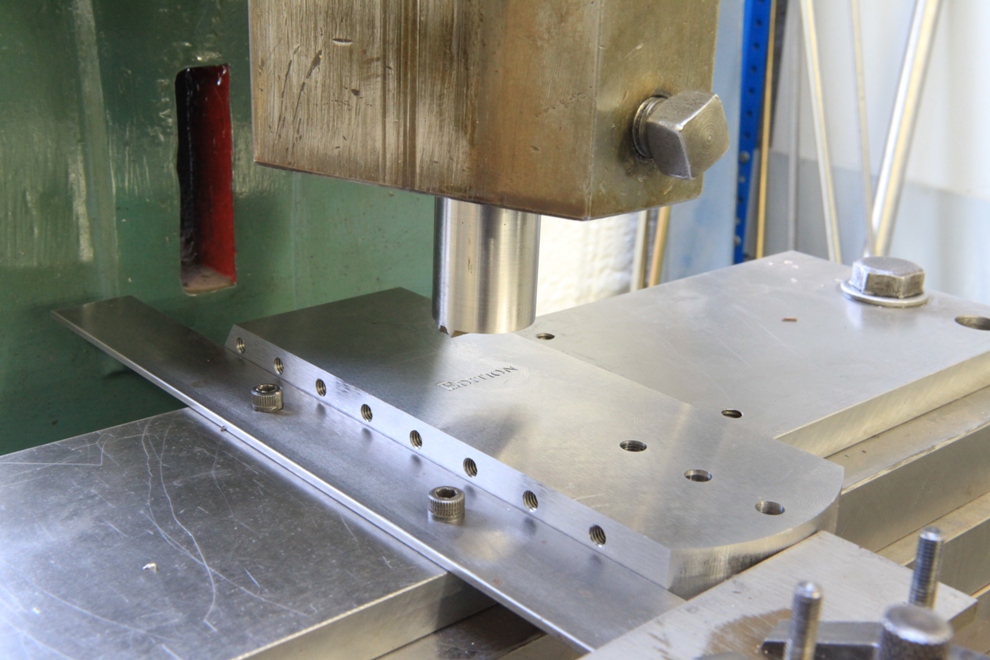

This picture here is the sides being ground true after the drilling and tapping. This also leaves the bottoms a true uniformed width and square.

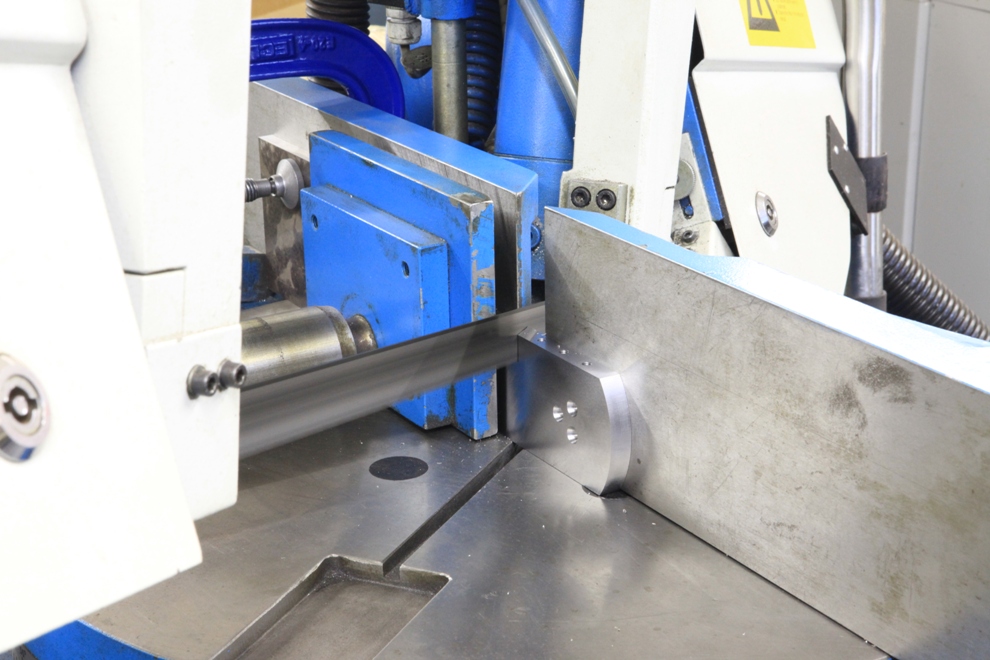

Of course the time comes when the toe of the plane needs to be separated from the rear end. I can lose a lot of sleep here as mistakes are so easy. Any mistakes here will cost me dearly.

With the front and back ends of the bottom now separated each part is then milled to size and angle.

All my marks are stamped with my fly press which I couldn’t exist without. The No 982 plane is stamped with an edition and its number, the plane type is stamped on the front end of the bottom (just behind the bun). The HOLTEY logo is stamped on the inside of the right hand side of the plane.

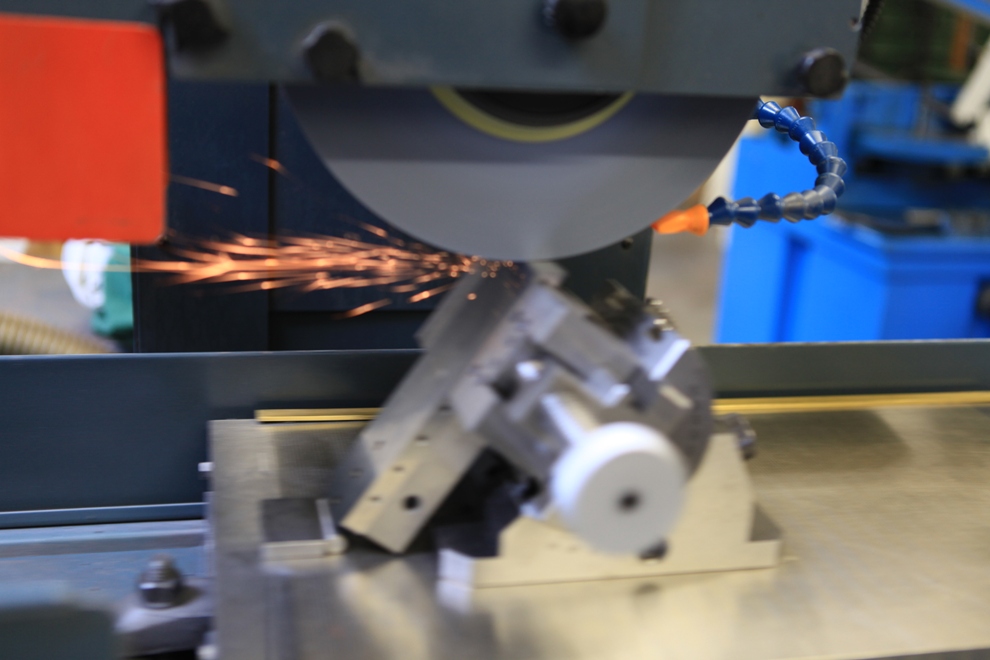

The 55 deg milled bed is surface ground maintaining the angle to precision. This picture may be a little blurred but I wanted to catch the sparks.

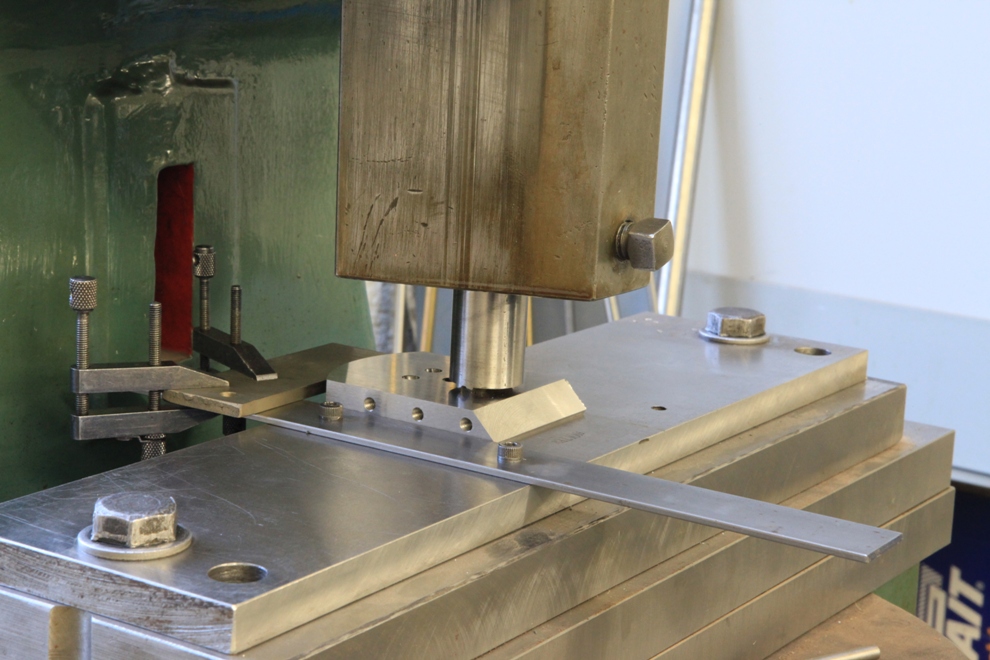

Now the front end. I use two angles here. The one being ground here is the critical one because this is going to be the mouth of the plane. This is in a similar tradition to some of the wooden planes and is much easier to regulate a small aperture as desired by some.

This angle here helps to provide a better means of escape for the shavings and access for cleaning. The grinding here is mainly cosmetic.

April 26, 2012

Window to my Workshop 63

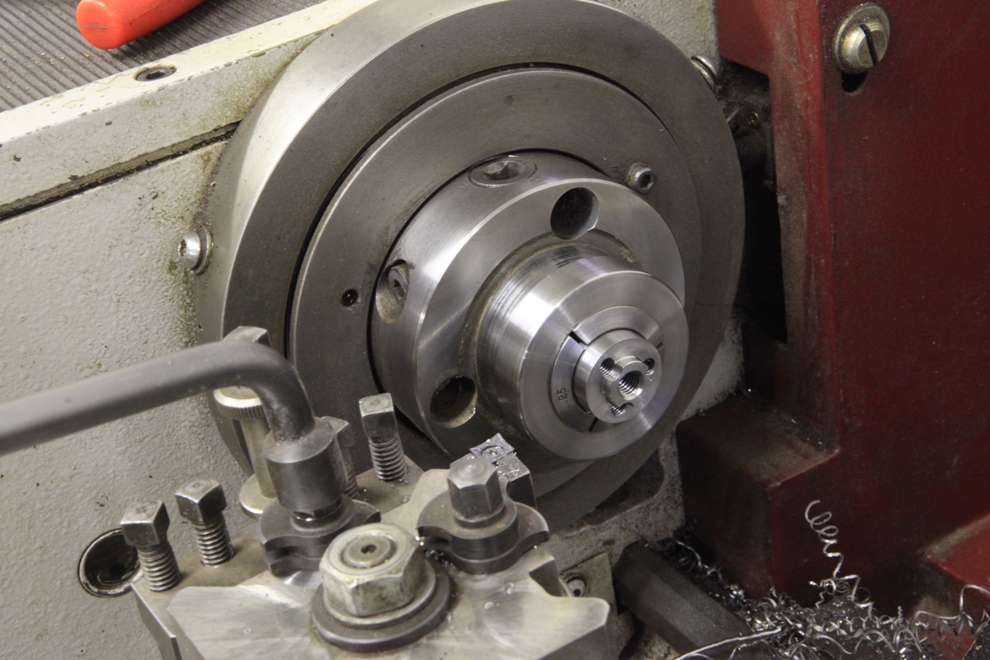

These are the front bun chairs and once the blanks have been cut and trimmed up true to uniformed size the central fixing hole is drilled whilst still in the lathe. They are then tapped with an 8 x 1.25mm thread; this is for the bun screw.

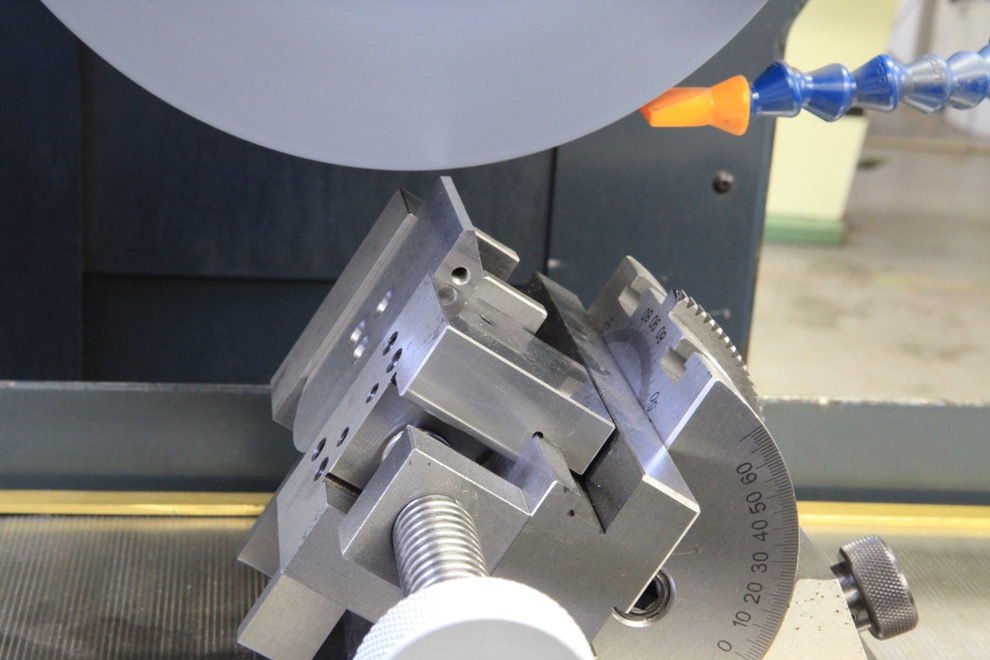

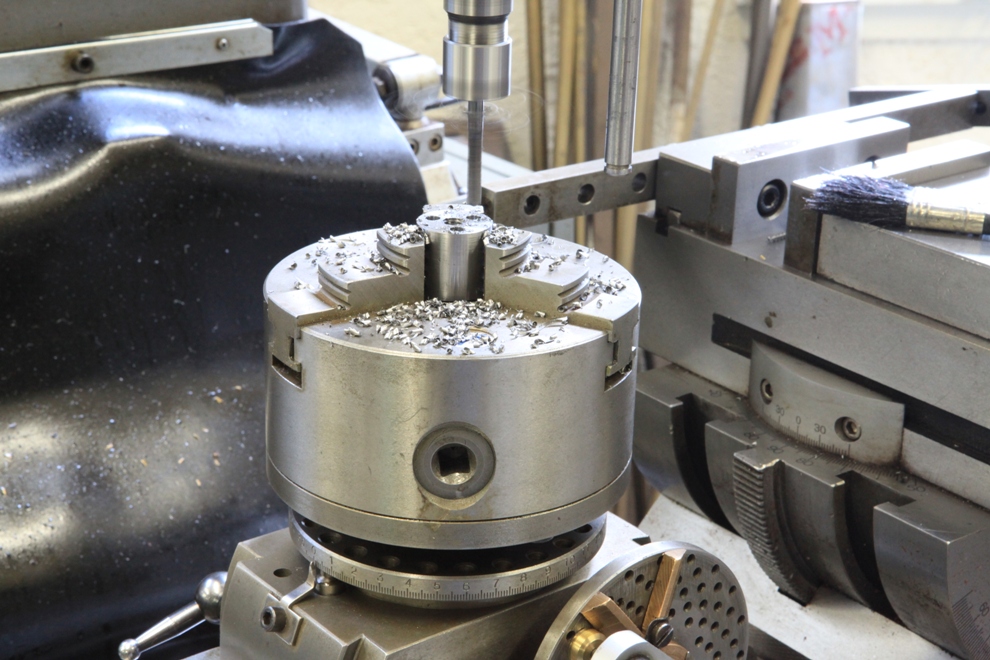

The 3 x 6mm fixings are drilled on a manual milling machine using an indexing head as shown.

With the three index holes now drilled I only need a tool change to tap these three holes whilst still in the chuck.

Now that all my fixing holes are complete it is back to the lathe to form a small spigot where the bun in engaged.

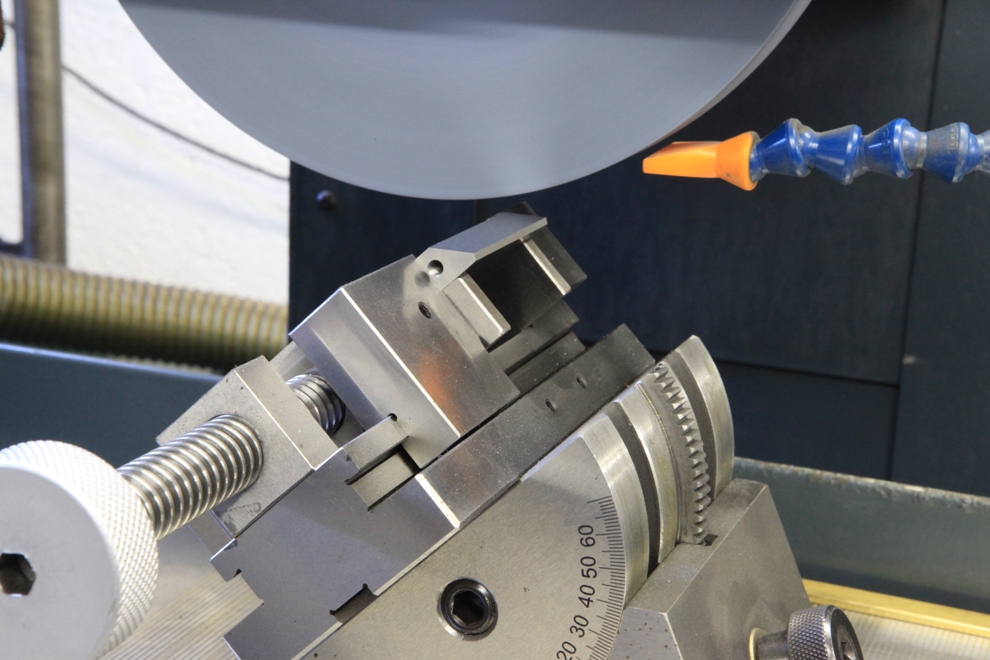

The last job on the chairs now is to finish the bottoms to the 15 deg offset to the front buns. A small fixture has been made for this purpose. The chairs are mounted with the three bolts.

The chair is held in its fixture and secured on the saw for cutting

Whilst the chair is still attached to the fixture it is clamped onto the tilting milling vice for surfacing to the desired dimension.

April 25, 2012

Window to my Workshop 62

Continuation from Blog 61

Now I have two flat sides the edges can be milled bringing them to width, leaving a couple of thou for surface grinding. This means that the edges will be perfectly square and will form an invisible joint. It is important that when the plane body is assembled everything is flat and square – unlike dovetailing which incurs a lot of stress from peining.

The rounding on the ends, a task easily carried out on the CNC mill.

This is the drilling for the 3 x 6mm purpose made bolts to fix the rear handle chair. I need to make some more of the bolts so will document them later on.

These three holes for the rear handle are then reamed (which I think is the correct word and not countersunk). This is done with a 40 deg tapered mill which will match the heads on the bolts. With this angle you get a good retention and pressure for some deformation, resulting in that invisible joint.

These are the fixing holes for the front bun using the same drilling and reaming operation as previously described. This time these holes are drilled at a 15 deg angle and indexed with 120 deg spacing. The CNC mill is particularly useful for indexing and convenient as I am drilling on a gradient.

The fixing holes for the sides. There are a total of 11 x 5mm holes per edge. As the holes are not drilled on the centre line they need to be mirrored. The picture shows my set up using a second vice for the mirror holes. To achieve this many holes without a CNC mill would be very stressful and time

My Semco vertical milling machine which is an exact Chinese copy of a Bridgeport. It is fitted with an Anilam Wizard 211 DRO. I have had it a for quite some years now and it serves me well.

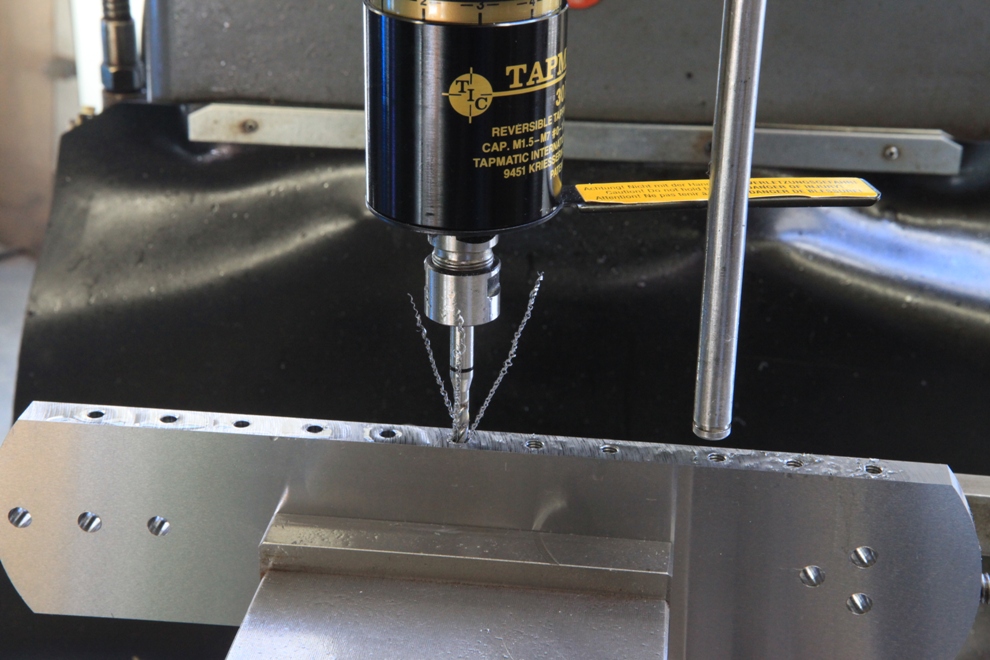

It is a pity that my CNC mill does not do tapping. So the plane bottoms had to be set up on the manual mill. However, with the aid of the DRO and an automatic tapping head the tapping of the holes is carried out to standard and in a timely manner. There are a few cheap tapping heads on the market but I would go for a Tapmatic every time, worth its money.