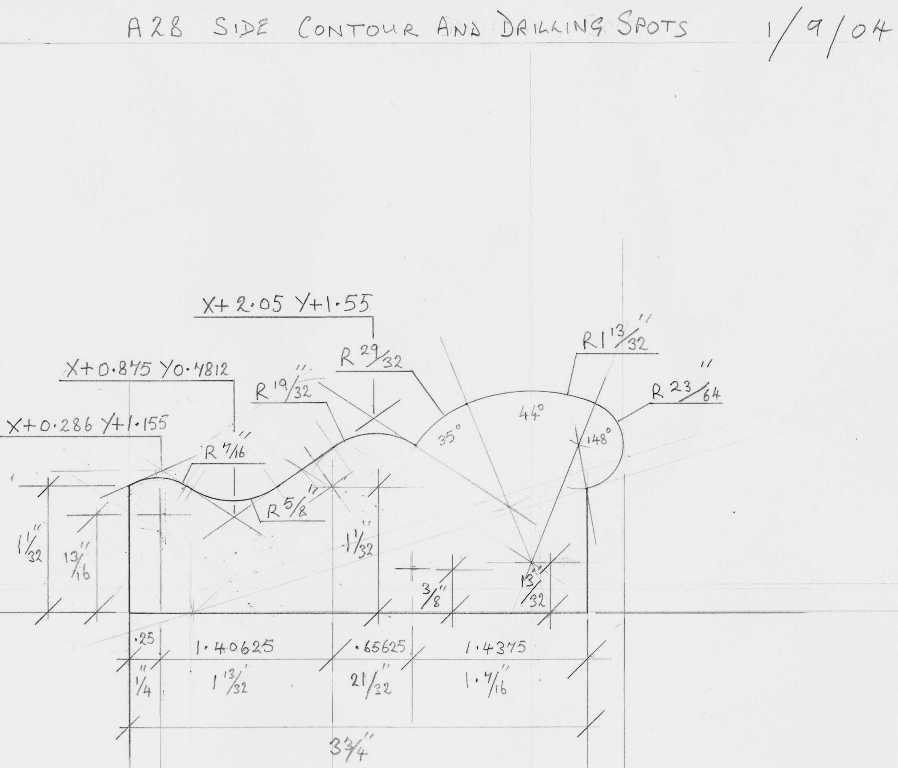

During the working of this A28 plane I have been neglecting this blog but now I am ready to update which I will do over the next few weeks.

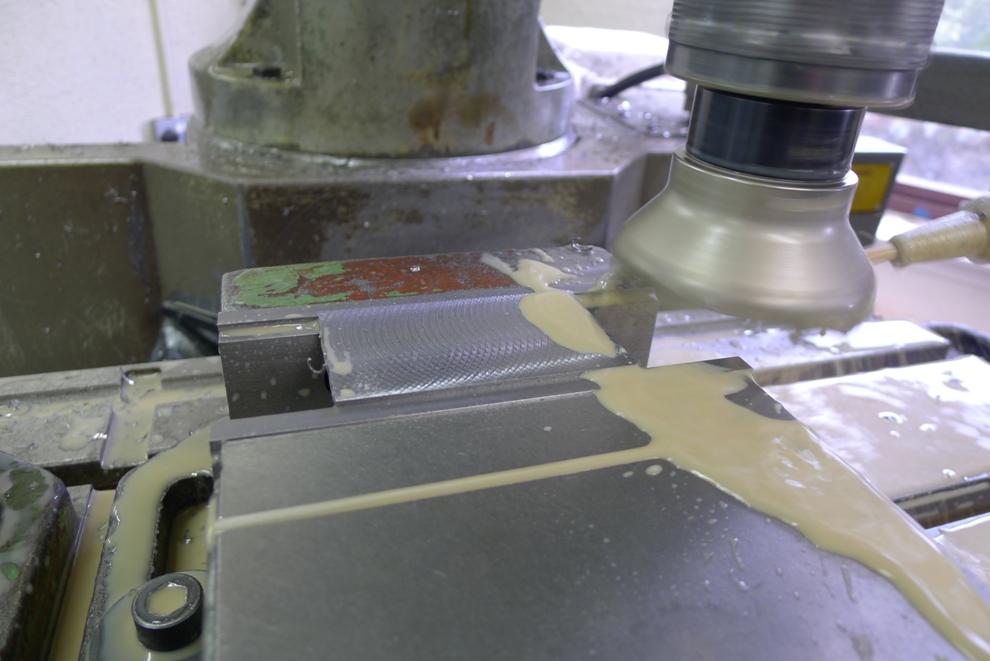

All the sections I use are cut out of stock material and brought down to size, by sawing and milling.

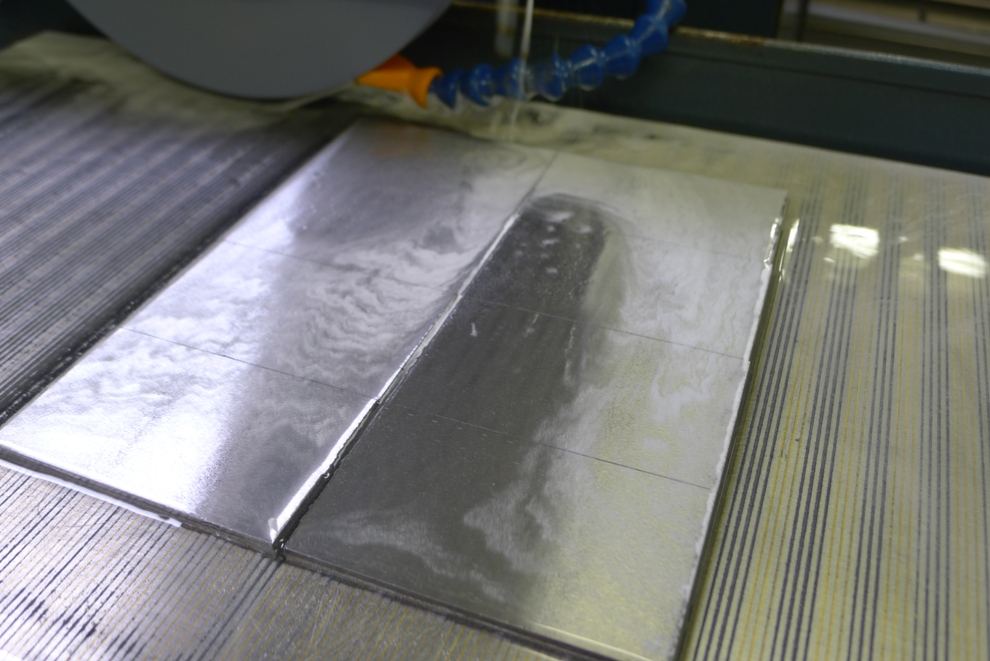

As most of my working and setting out depends on a high degree of precision (which has never existed before) surface grinding in the early stages allows me to achieve my goals.

This picture shows the edges being ground. This is also important to have a true pinch dimension. I need this for the dovetailing.

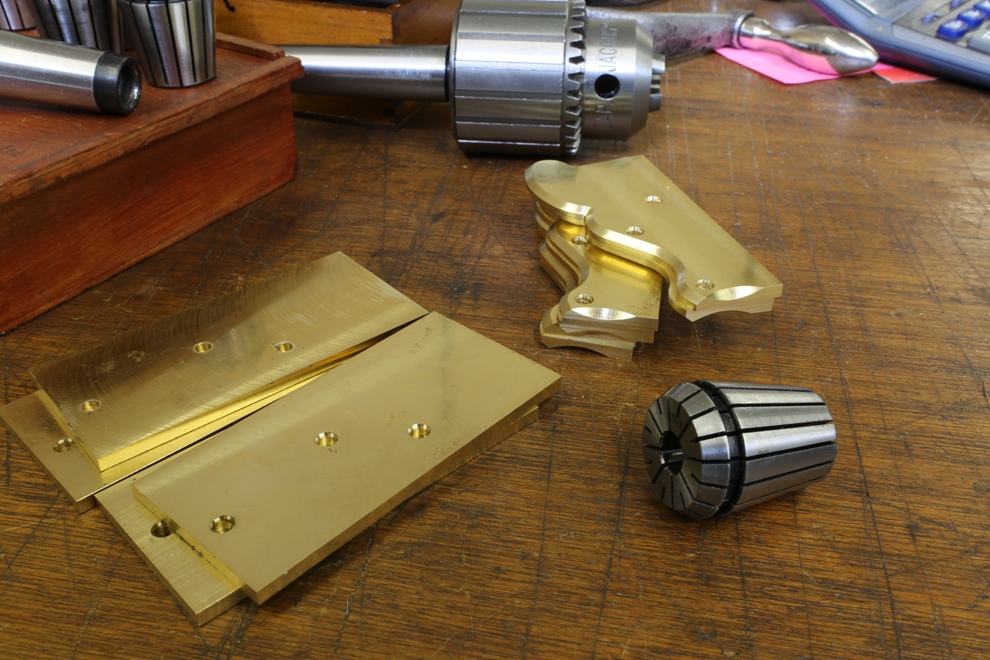

Jigs and work holding fixtures are also all made to precision. After much preparation work to the brass, similar to the steel work as described. Then rivet positions are drilled and I am able to screw these sides with purpose made bolts to the fixture for profiling and chamfering.

After routing out the profile then the chamfering is completed whilst the sides are still jigged.

Just overall set up pictures.

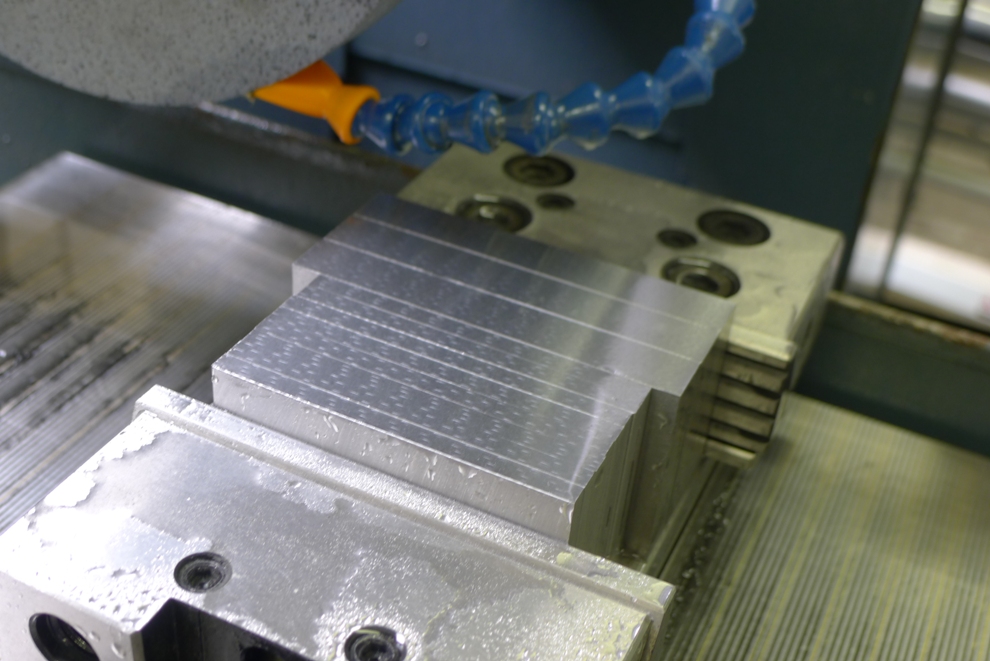

Here are the some sides already milled and some pre-prepared waiting for profiling.