A few more pictures to conclude the subject of polymer. Feel free to comment on whether it is worth it when you have seen the finished product.

Hopefully this plane will be on exhibition at the WIA conference next month with The Best Things.

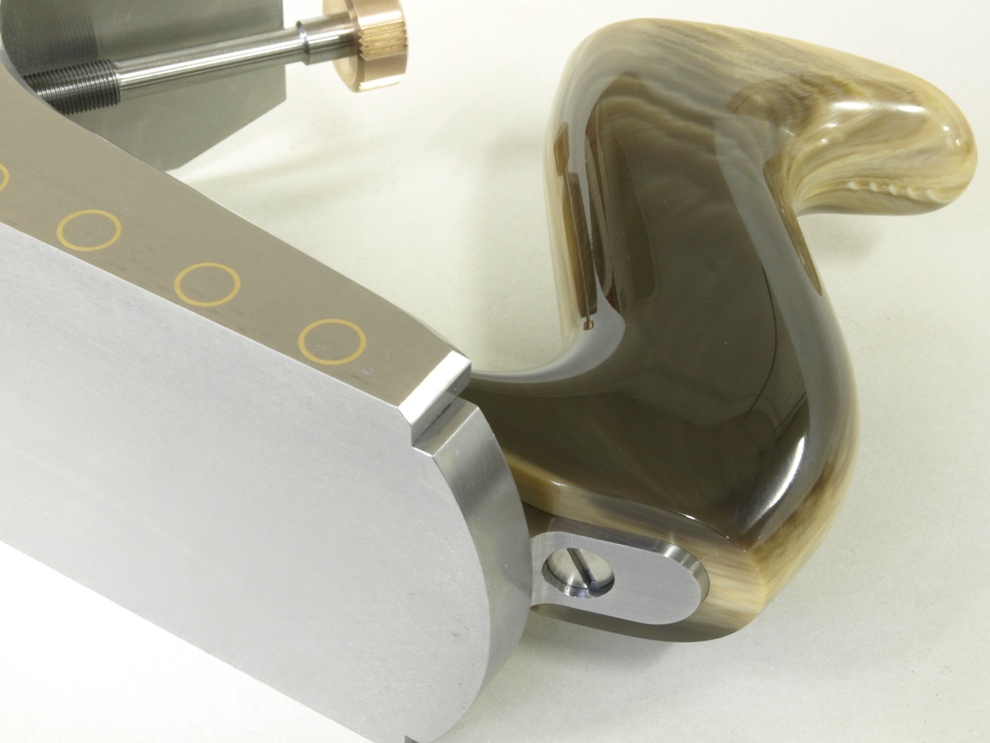

As you can see the polymer is worked in the same way as wood and the shaping is all done by hand.

Another view showing the fixing recess.

After many hours of polishing, the handle is fixed by the one screw connecting the stainless steel spine inside the handle. It is also secured by the handle’s recess and boss/chair.

I just found this picture of a rosewood handle. It shows the stainless steel inner parts of the handle and bun. Note the flats on the coarse thread for the bun (there are 3). There are also flats to be filed onto the handle spine as well. When these are cemented into position they cannot work loose or be undone.

I would like to clear up a small criticism on the fixing of the rear wooden handles, whereby the screw can work loose within the handle spine. The handles are pulled down into position from the top of the handle so it is compressing the wood across its grain, which holds the handle tight into its seat. Wood expands and contracts all the time so this screw does need to be checked from time to time. This is a simple task it just needs a little tighten with a screwdriver. There are some low strength thread locking compounds which can stop any threads from moving and are ideal for adjustment purposes but this still doesn’t solve the problem of the wood expanding and contracting. Of course one of the advantages with the polymer is it being dimensionally stable so this will not happen.

Front section of plane showing the canted bun in position.

Finished plane showing the rear and some of its mechanism

Now is it worth it?

Return to main page

just when we think you cannot improve ,you come up with another little anomaly to stop us in our tracks .

Keep up the blog material it keeps us wannabes on the trail .

Comment by taffioca — September 20, 2010 @ 9:29 pm

Hi taffioca

You’re quick, I’ve only just uploaded it! Thanks for the comments and compliments.

k

Comment by admin — September 20, 2010 @ 9:35 pm

*Drooling*

B

Comment by Adrian Baird Ba Than — September 20, 2010 @ 10:26 pm

i must say that i am really on the fence about the polymer handles (keeping in mind that this is without seeing it in person). i like the idea of the stability of the material and i think i would prefer a darker colour.

how does it compare to wood for its feel in the hand?

cheers, michael

ps many thanks for the blog, it is much appreciated

Comment by michael — September 20, 2010 @ 10:26 pm

Karl: now that you,ve answered the material movement problem how do you think your customers would handle an infill plane made with a polymer? Maybe a black material with a grain to aproximate ebony. Great work as always.

Comment by George — September 21, 2010 @ 1:14 pm

Karl –

Excellent as usual, but surprisingly excellent given that it’s polymer and doesn’t look like a bowling ball from the 1950s. I still prefer wood and wouldn’t mind turning the screw when it needs tightened, but I have to say that is the finest looking polymer I’ve seen. If I glanced at it and someone told me it was polymerized horn or something, I would believe them.

I recognize that even with the preference of wood, the polymer is far more practical.

Of course, the usual level of finish and laser crisp fit that those of us clanking together planes could only dream of producing, too.

Best –

Dave

Comment by David Weaver — September 21, 2010 @ 2:49 pm

Hi Michael

There doesn’t seem to be any darker colours available except for ebony.

The polymer doesn’t feel much different from wood, perhaps very slightly more grip.

k

Comment by admin — September 21, 2010 @ 4:49 pm

Hi

I think the polymer would go well in a mitre plane or one in the style of my 11-sa. The horn sample that I used contrasts nicely with brass. I would think that the ebony type you can get would look a bit like plastic. I might get a sample though to see.

k

Comment by admin — September 21, 2010 @ 4:52 pm

Hi Dave

I’ll keep making the planes, you keep making the nice comments!

k

Comment by admin — September 21, 2010 @ 4:53 pm

Hi Karl, I think the 982′s exposed brass cones makes the tortoise shell polymer work really well with this particular plane, I like it.

Cheers,

Steve

Comment by Steve C — September 22, 2010 @ 12:23 am

I THINK THE POLYMER TAKES IT TO A WHOLE NEW LEVEL IN APPERENCE.WONDERFULL IDEA.CAN YOU TELL ME WHERE I CAN BUY THE MATERIAL.THANKS FOR THE PICS.

Comment by lou tucker — September 23, 2010 @ 3:01 pm

Thanks Lou, have look at: http://www.ivoryalternative.com/

Comment by admin — September 23, 2010 @ 9:44 pm

hello Karl,like most people involved with this wonderful business of working wood I think your planes are second to none with a complexity hidden by deceptively simple beauty and purity of form,I wondered what difference (if any) it would make to have the brass cones in bronze?

Comment by peter witty — June 8, 2011 @ 10:55 pm

Hi

I think the brass is easier to work than bronze and am not sure that bronze would lend itself to this application. Maybe I will look at this in the future; the bronze will make a much stronger contrast.

Having made a bronze mitre plane in the early days (it would be interesting to know where this is now) it acquired a colour and finish of its own very quickly. This was induced by lots of handling and finger marks which gave it a dark brown marbling effect.

“a complexity hidden by deceptively simple beauty and purity of form” This is my objective and it has also been said by a well known manufacturer that I hide all my work, but it is nice when people pick it out.

Thank you for your comments.

k

Comment by admin — June 9, 2011 @ 8:45 am