This is unusual for me because I think showing off shavings could be a little sad. Not many people tell you the wood they are using but here I have planed a very wild piece of Boxwood out of the scrap bin. As you can see there is a large knot near the edge so there is a lot of alternating grain. I was pushing off quite a thick shaving at 2 thou with no tear out at all. Then I was able to finish off at 1 thou without revisiting the oil stone. No doubt the enthusiast could improve on this performance as I don’t have the time to play. This is my new blade in stainless – that is all I am saying.

September 21, 2019

September 20, 2019

September 19, 2019

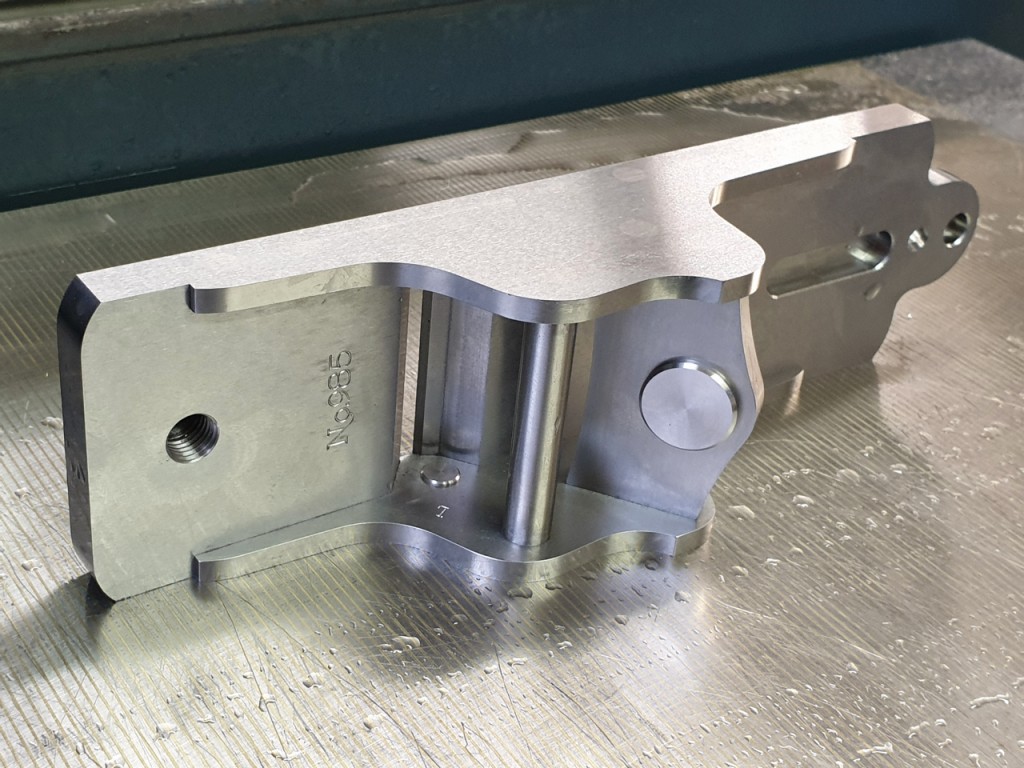

Workshop blog no 32 – No 985

It has been a very long journey but at last the planes are ready. I have always said that I try to improve over the preceding planes which is always a difficulty and this one clearly does it.

September 18, 2019

September 17, 2019

Workshop blog no 30 – No 985

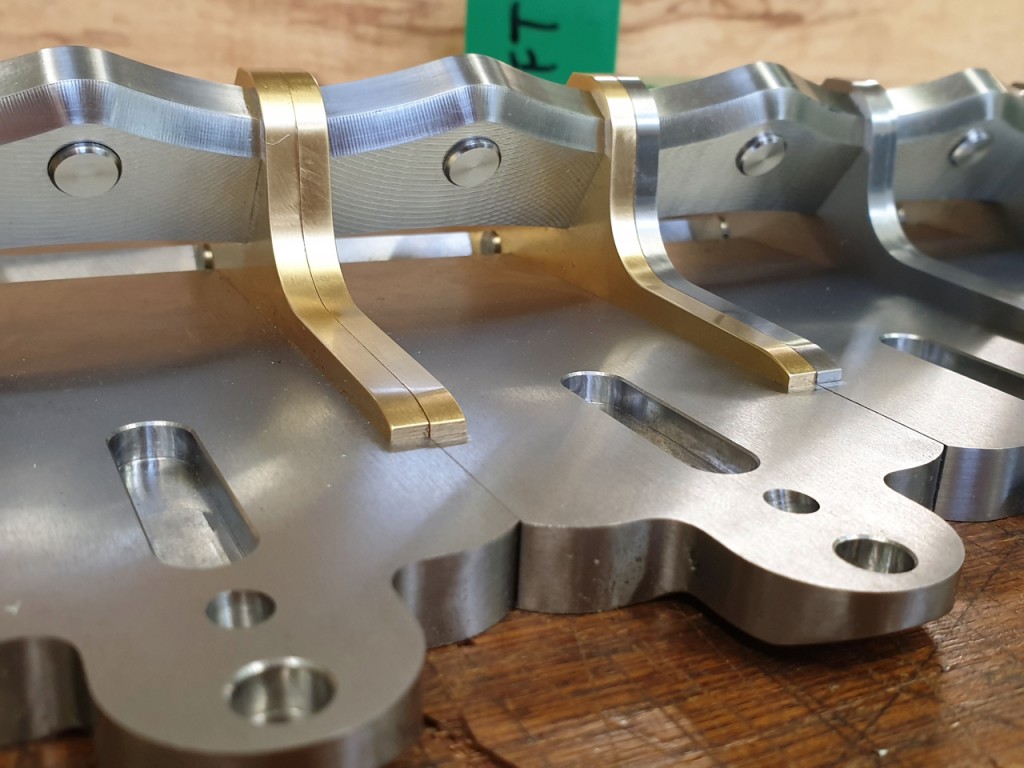

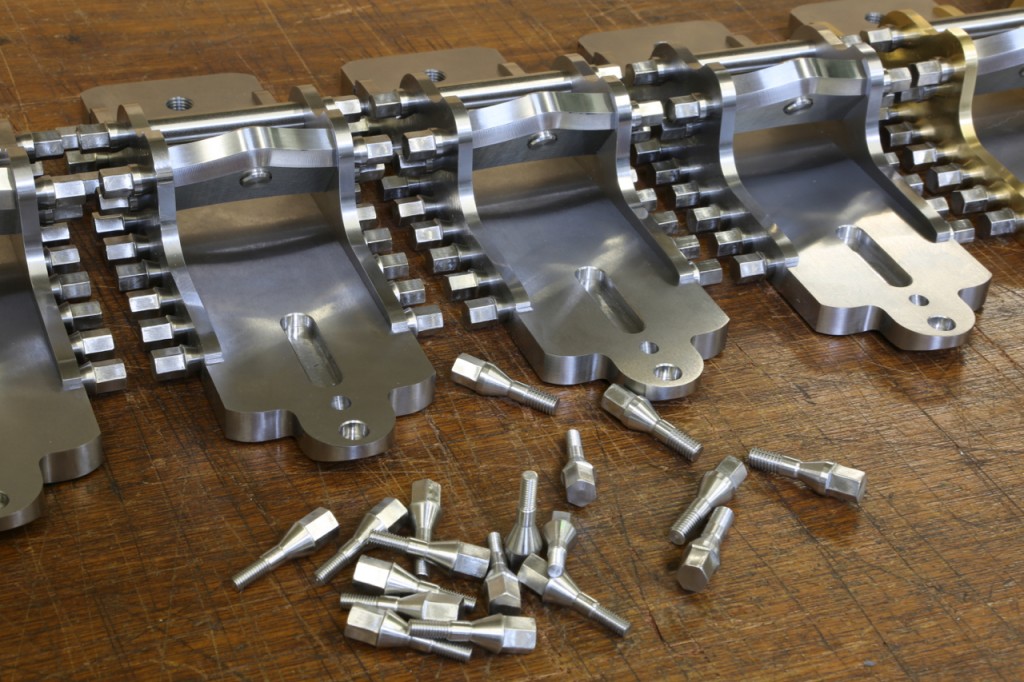

Photos showing the bolts trimmed, milled and surface ground. This plane has probably been the best of all my work and one of the most important factors is the much heavier chassis. I have been able to work to very much tighter milling tolerances, in fact well under 1 thou. It has helped on the grinding because I need to take less off – stainless steel is very difficult for grinding and I can only take cuts of .0002″ (that is 2/10 of a thou). The more cuts you take from stainless the harder the material becomes. You also have to be continually wheel dressing even with using a ceramic wheel. This is the real work that I enjoy the most.

September 14, 2019

Workshop Blog no 29 – No 985

The bolts have been thread locked with Loctite 270, so things should be moving along very quickly now.