I wish this stainless stuff would cut as easy as the plastic. The plastic is very useful for setting up.

This is quite a heavy cut for my machine and she it is getting quite old. So it always nice to put these jobs behind me.

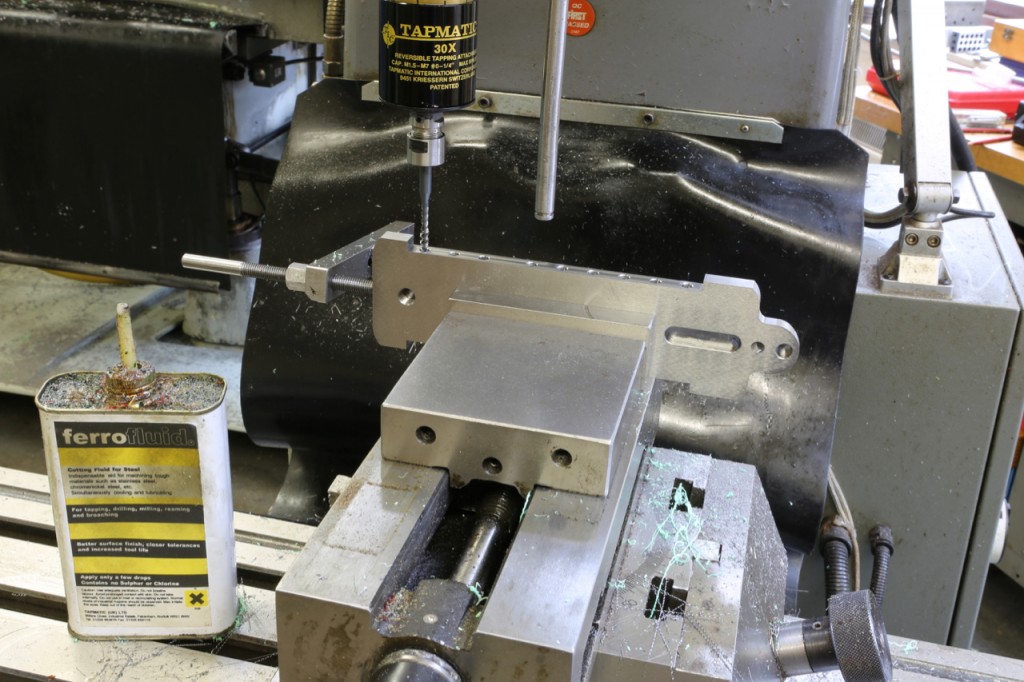

With the recesses now cut I am still not out of the woods as the drilling for the custom made screws makes me worried about tool breakage – set up is critical. The drilling stage is three different tools.

The tapping is the most dangerous part of this stage and I always take a sigh of relief if I finish without incident. One tap breakage means I am minus a plane – that is a lot of work gone down the toilet! It is not like a production line and every plane is relied on to show a profit.

Every stage of this work has to be a well planned operation to avoid any casualties.

Thanks for sharing these pics. Voyeuristic as we may feel, for many of us this is as close as we will ever get to a Holtey plane. If you broke a tap could you not bore it out and refill the hole to re-drill and tap? I suspect that would be a breach of your atmospherically high quality standards?

David

Comment by jimjam66 — April 12, 2019 @ 4:01 pm

Thanks David, you answered it for me!

More blog to come soon

Karl

Comment by admin — May 8, 2019 @ 9:41 am