I want to show off some of the finer detail in the making of my adjuster components and the tooling used to make them.

These are for my low angle planes:

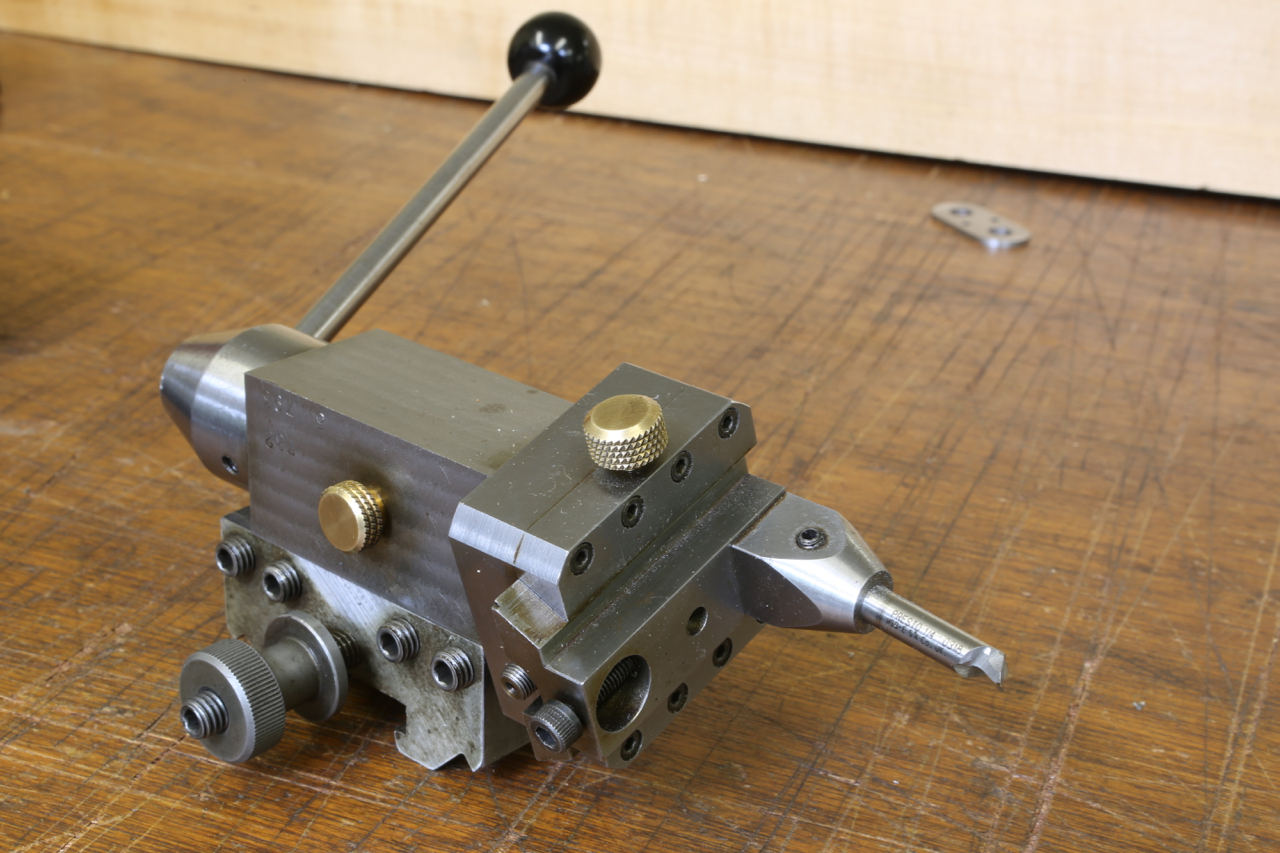

This is a ball turner I made 30 years ago in the days when I was very enthusiastic for making miniature locos. Over time it has been used a lot in the making of my planes.

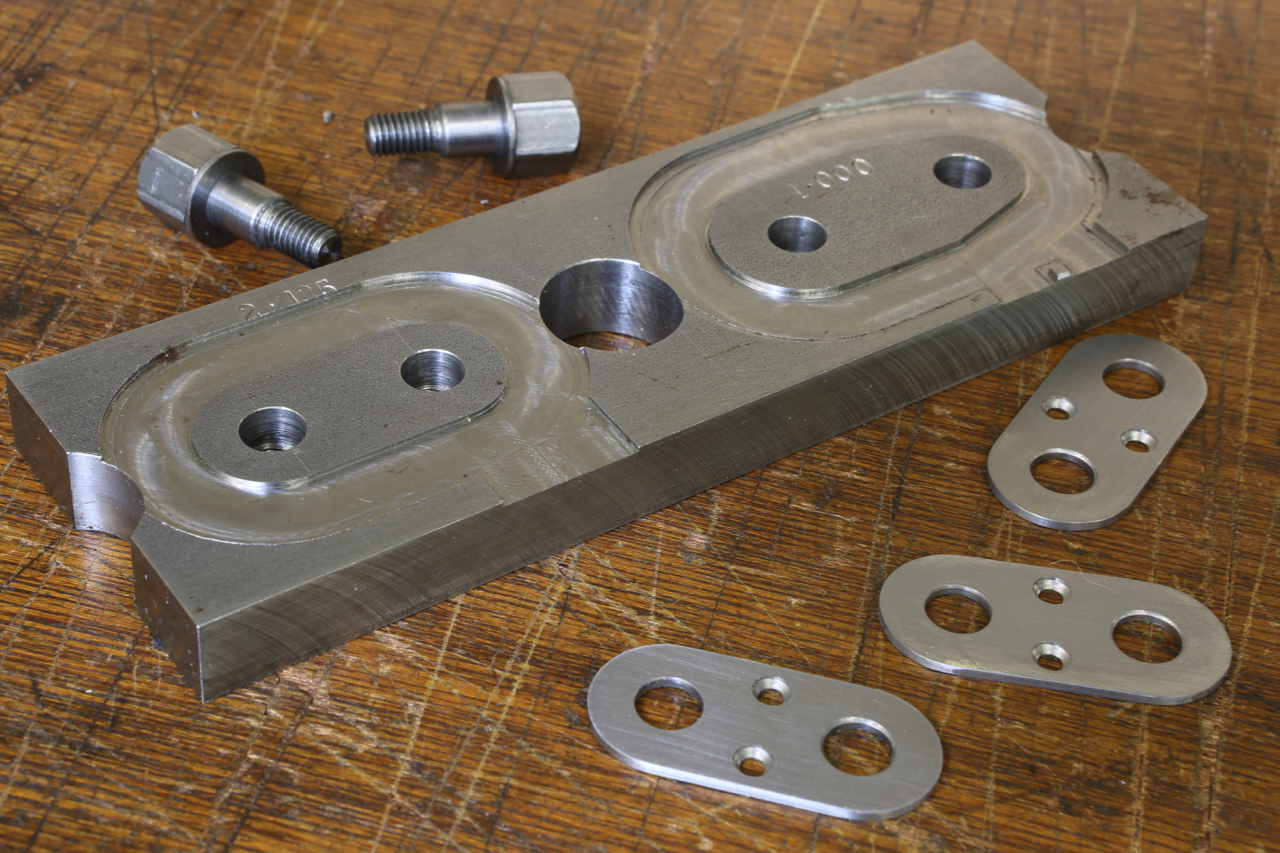

A fixture I made which is used for making my adjuster bases.

After the threaded stem and body has been ball turned a flat is needed so that it glides freely over the adjuster base and helps to orientate the blade driver. This is the flat after milling.

This is the blade drivers at different stages of their making. Two of which are still attached to their carriers, and one finished.

The last stage in the making of this blade driver is to turn the spigot on to its body. I had to make a special collet which was a little bit fussy because the spigot has to be formed 8 degrees from the perpendicular. Unlike the Norris counterpart it is all in one piece. Norris never went this far.